Solvay commissions new sodium bicarbonate plant in USA to serve growing demand for flue gas cleaning

Process reclaims and transforms manufacturing waste into new Select S300 sodium bicarbonate for use in pollution control solutions in the USA

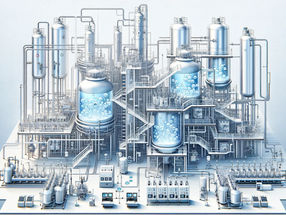

Solvay announced that its American affiliate Solvay Chemicals, Inc. has commissioned and brought online one of the world’s only dedicated manufacturing facilities that reclaims and transforms sodium carbonate waste streams from processed trona into a marketable grade of sodium bicarbonate. The new product, SOLVAir® Select 300, is ideally suited for flue gas emission control applications in the USA. The new installation has an annual capacity of 125,000 tons and required Investment of 26 million USD.

The manufacturing process delivers a two-for-one environmental benefit by reclaiming wastes that would otherwise be shipped to a detention pond, and also by creating product that directly helps coal-fired power plants reduce SO2 and other acid gas emissions. The unique process remanufactures the waste stream, transforming it into a sodium bicarbonate product with performance characteristics that are well suited for desulfurization applications.

“Today represents more than five years of hard work and collaboration across two continents between a talented group of Solvay engineering and manufacturing professionals,” commented Christine Tahon, General Manager of Solvay’s Strategic Business Unit Soda Ash. “We achieved an environmental and technical milestone within our industry and underscored Solvay’s commitment to being at the forefront of sustainable Chemistry.” “With ever tightening emission control standards in the USA, our power generation customers are seeking new and cost-effective solutions for their operations,” adds Mike Wood, SOLVAir Products Senior Business Manager.

Most read news

Other news from the department manufacturing

Get the chemical industry in your inbox

From now on, don't miss a thing: Our newsletter for the chemical industry, analytics, lab technology and process engineering brings you up to date every Tuesday and Thursday. The latest industry news, product highlights and innovations - compact and easy to understand in your inbox. Researched by us so you don't have to.