On the way to lead-free technology

The change-over to lead-free products is in full progress. The problem is however that the environmentally friendly alternatives have to be as effi cient as the lead-containing variants. One example is the injection system of diesel engines. Lead-free functional materials can be found faster by means of computer simulation methods.

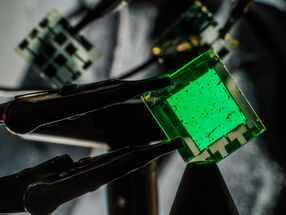

Technical progress in the automobile industry is unbroken. But, the sector has still some hard nuts to crack: “Lead-free materials” is one of the challenges – hidden behind this challenge is a EU environmental directive which, based on a step-by-step plan, gradually bans all lead-containing materials and components from automotive vehicles – such as piezoelectric components. These elements are important for diesel engine injectors, for example, which control the supply of fuel to the combustion chamber.

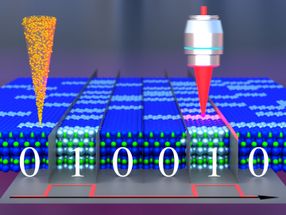

The problem: Up to now lead-zirconate-titanate (PZT) is the material of choice when fast switchable piezoelectric applications in cars are concerned. To find alternatives without containing the heavy metal of lead is not an easy task, however, because in raw condition all alternatively used materials still do not have the desired properties. A simulation approach which the researchers of Fraunhofer Institute for Mechanics of Materials IWM have developed gets the search going now: “We have to chemically and physically modify the potential candidates in such a way that in the end the replacement materials behave similarly well as the PZT“, says Professor Dr. Christian Elsässer, group leader at the IWM. A candidate such as this is potassium-sodium-niobate (KNN). Like PZT it is a ferroelectric monocrystal, but as technical ceramics with uncontrolled atom vacancies and grain boundaries in the crystal lattice, KNN is initially useless as a material. “For this reason, we have to make a virtue of necessity and have to introduce the right doping, i.e. foreign atoms, in order to improve the properties of the ceramic KNN,” says Christian Elsässer.

Where and how these doping atoms have to be introduced is figured out by the researchers by means of computer simulation: Different ferroelectric properties are obtained depending at which position of the crystal lattice the foreign atoms – such as copper – are placed. “At one position, the copper donates electrons, at another position it prefers to accept them. Dipoles are formed or they are not formed depending on the lattice position,“ explains Christian Elsässer. These solid-state physical parameters and a number of others shall be determined in advance. Researchers do this with the help of “physics in the computer”. This is by no means a trivial task because the quantum mechanical computations require complex atom model systems and big computer capacity. But on the other hand, a lot of time and money can be saved in the development of materials, because on the one hand fewer synthesis and analysis experiments in the laboratory are required. On the other hand computer simulation also produces important thermodynamic parameters for the sintering process, such as pressure and temperature ranges at which the components have to be manufactured. ”The engineers receive synthesis instructions for the material at the same time,” says the researcher.

In this way, the automobile industry can achieve the lead-free target faster. But not only this sector profits from Fraunhofer technology. Lead-containing materials are also present in frequency filters of mobile phone or in mechanical sensors and actuators. Ferroelectric capacitor components are competitive in the race for records when it comes to saving ever bigger data volumes on the smallest of space.

Other news from the department science

Get the chemical industry in your inbox

From now on, don't miss a thing: Our newsletter for the chemical industry, analytics, lab technology and process engineering brings you up to date every Tuesday and Thursday. The latest industry news, product highlights and innovations - compact and easy to understand in your inbox. Researched by us so you don't have to.

Most read news

More news from our other portals

See the theme worlds for related content

Topic world Synthesis

Chemical synthesis is at the heart of modern chemistry and enables the targeted production of molecules with specific properties. By combining starting materials in defined reaction conditions, chemists can create a wide range of compounds, from simple molecules to complex active ingredients.

Topic world Synthesis

Chemical synthesis is at the heart of modern chemistry and enables the targeted production of molecules with specific properties. By combining starting materials in defined reaction conditions, chemists can create a wide range of compounds, from simple molecules to complex active ingredients.

Topic world Sensor technology

Sensor technology has revolutionized the chemical industry by providing accurate, timely and reliable data across a wide range of processes. From monitoring critical parameters in production lines to early detection of potential malfunctions or hazards, sensors are the silent sentinels that ensure quality, efficiency and safety.

Topic world Sensor technology

Sensor technology has revolutionized the chemical industry by providing accurate, timely and reliable data across a wide range of processes. From monitoring critical parameters in production lines to early detection of potential malfunctions or hazards, sensors are the silent sentinels that ensure quality, efficiency and safety.