Linde to construct on-site plants for Sadara's major chemical complex in Saudi Arabia

Total investment: USD 380 million

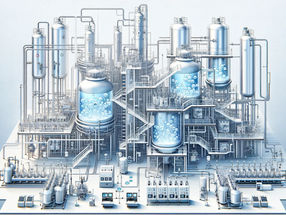

The technology group The Linde Group and Sadara Chemical Company (Sadara) recently signed a long-term contract that will see Linde supply Sadara with carbon monoxide (CO), hydrogen (H2) and ammonia (NH3) at a chemical complex now being built by Sadara in Jubail, Saudi Arabia, which will be the world's largest chemical complex ever built in a single phase. The on-site gases supply contract includes a HyCO facility for the production of CO and H2plus an ammonia plant. Linde will be investing USD 380 million in the project. Sadara, established in October 2011, is a joint venture developed by Saudi Arabian Oil Company (Saudi Aramco) and The Dow Chemical Company (Dow).

"This contract is an excellent opportunity from several perspectives," states Professor Dr Aldo Belloni, Member of the Executive Board of Linde AG. "It is Linde's largest on-site petrochemical project in this region, and our first in Jubail. It thus strengthens our position as a global leader in the generation and supply of carbon monoxide for MDI and TDI production plants at integrated chemical hubs. The petrochemical industry is expanding rapidly in Saudi Arabia. We expect that this growth will give added momentum to the expansion of our gases and engineering business in the Middle East."

Linde's Engineering Division will design, deliver and construct the new turnkey gases facilities at Sadara's site in the Jubail 2 petrochemical cluster. The company will be building a two-stream HyCO plant, plus a single-stream NH3 unit producing waterless liquid ammonia. Linde will also install a large NH3 storage tank, resulting in a sophisticated supply concept which will enable the plant to run smoothly and reliably at all times. The production units are scheduled to be ready in 2015. Once built, they will be operated by Linde's Gases Division. Linde is setting up a local gases company for on-site support.

Sadara will use carbon monoxide, hydrogen and ammonia primarily for the production of aromatics, isocyanates (MDI and TDI), amines and hydrogen peroxide. Methylene diphenyl diisocyanate (MDI) and 2,4 toluene diisocyanate (TDI) are used in the production of polyurethanes – an essential component in many products ranging from synthetic fibres through insulating foam and adhesives to mattresses and car seats.

Sadara will construct, own and operate a world-scale integrated chemicals complex in Jubail Industrial City II in Saudi Arabia. Sadara will have a differentiated product mix, most of which are produced locally for the first time. This differentiation will create further growth opportunities for conversion and downstream industries in the adjacent PlasChem Park.

Most read news

Topics

Organizations

Other news from the department manufacturing

Get the chemical industry in your inbox

From now on, don't miss a thing: Our newsletter for the chemical industry, analytics, lab technology and process engineering brings you up to date every Tuesday and Thursday. The latest industry news, product highlights and innovations - compact and easy to understand in your inbox. Researched by us so you don't have to.