Boom in bubble columns: One of the most important types of reactors in the chemical industry is set to become more efficient

Evonik Industries has been operating a bubble column test facility in Marl (Germany) since May 2014 with the aim of optimizing this process technology, which is very important for Evonik. With this facility, the specialty chemicals company is accumulating additional knowledge about Hydroformylation, a process used in the company to synthesize aldehydes, a starting product for specialty chemicals.

Dr. Claas Klasen, Head of Process Technology & Engineering at Evonik, explains, "We are expanding our existing outstanding technological competence by improving our understanding of bubble columns. By doing so, we will make chemical production even more efficient, more energy-saving, and produce fewer emissions, all of which contribute towards sustainable chemistry."

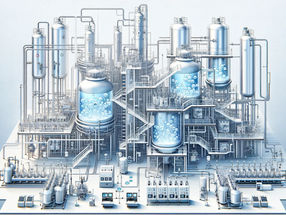

Bubble columns are one of the most important pieces of production equipment in the chemical industry. As well as aldehydes, Evonik also uses the reactors to produce hydrogen peroxide, an oxidizing and bleaching agent. Throughout the world, the chemical industry produces about 50 million metric tons of materials in bubble columns. "Our goal is to speed up planning of large production plants and facilitate development of new processes and methods," says Prof. Robert Franke, who is responsible for research into hydroformylation in Evonik's Advanced Intermediates Business Unit.

Simple basic principle: gas bubbles through liquid

Basically, bubble columns are large tubes in which a gas bubbles through a liquid from the bottom to the top. At the boundary surface between the gas and the liquid the chemical reaction takes place, which creates the desired product. For example, Evonik produces aldehydes through hydroformylation of olefins with syngas.

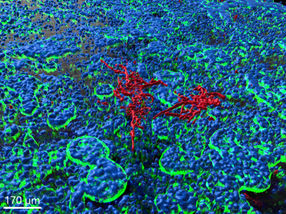

While bubble columns are quite simple pieces of equipment from a mechanical aspect, the processes that take place within them are very complex. The processes that occur in the reactors can be described with the help of computational fluid dynamics (CFD). However, there is little data available for transferring this to actual systems in the chemical industry, since only water-air systems have been investigated in the past.

Dr. Marc Becker, one of Evonik's leading process engineers in Marl, explains, "The actual processes in the chemical industry are much more complex. We want to discover more about what actually happens between the gas and liquid phase in an actual bubble column that is several meters high with trays, heat exchangers, and packing and how the multiple phase system behaves in the column." In the past, there have been no reliable modeling or measuring technologies available to back up the evidence for the models. This is where the Multi-Phase project—which the German Federal Ministry of Education and Research (BMBF) is sponsoring with €3 million—comes into play. Evonik initiated the project together with partners in universities, research centers, and SMEs.

Multi-Phase project further develops models and methods

One of the tasks of the project partners was to develop and optimize a measuring technology for pilot and production reactors. Another task was to calculate new models for bubble columns and to validate them on the basis of specific measurements. Various test substance systems were investigated, such as the solvent acetone and nitrogen gas. When the project is concluded in April 2015, open source software will be available that all interested parties can use and continue to develop. Becker is already quite confident, "The findings can be used on a broad basis for various reactions and will produce several improvements in terms of cost effectiveness and also as regards the energy and resource efficiency of chemical plants."

Evonik uses test facility for actual process

The work that Evonik commenced in the bubble column test plant in May 2014 is based on findings from the Multi-Phase project. The bubble column in the test facility is four meters high and was installed for the test phase of the BMBF project at the Marl Chemical Park. Now that the test phase is over, Evonik is using it for the actual substance system olefin and syngas. Becker explains, "With the help of the new measuring technology from the Multi-Phase project, it is now possible to observe the system for a long period and, by doing so, to get a better understanding of the reaction that is taking place." The reactor will then be used to trial new production processes for the manufacture of plasticizer alcohols and specialty chemicals – also using various catalysts with variations in pressure and temperature.

Most read news

Other news from the department manufacturing

Get the chemical industry in your inbox

From now on, don't miss a thing: Our newsletter for the chemical industry, analytics, lab technology and process engineering brings you up to date every Tuesday and Thursday. The latest industry news, product highlights and innovations - compact and easy to understand in your inbox. Researched by us so you don't have to.