Scientists develop force sensor from carbon nanotubes

A group of researchers from Russia, Belarus and Spain, including Moscow Institute of Physics and Technology professor Yury Lozovik, have developed a microscopic force sensor based on carbon nanotubes. The device is described in an article published in Computational Materials Science.

A group of researchers from Russia, Belarus and Spain, including Moscow Institute of Physics and Technology professor Yury Lozovik, have developed a microscopic force sensor based on carbon nanotubes.

Computational Materials Science Journal

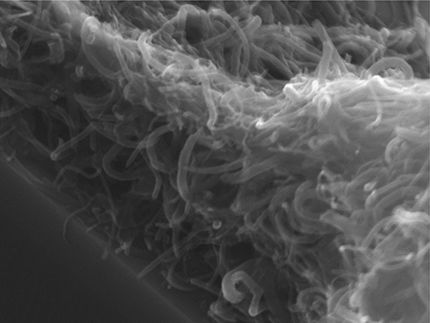

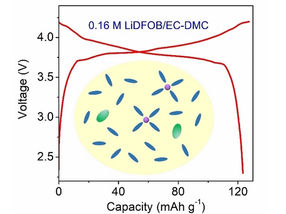

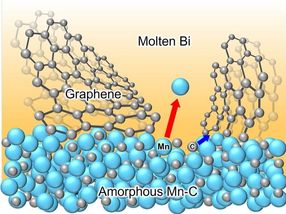

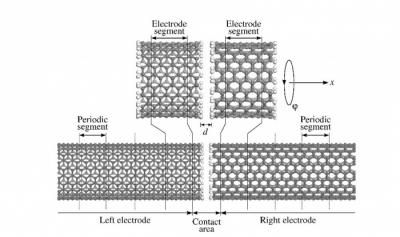

The scientists proposed using two nanotubes, one of which is a long cylinder with double walls one atom thick. These tubes are placed so that their open ends are opposite to each other. Voltage is then applied to them, and a current of about 10nA flows through the circuit.

Carbon tube walls are good conductors, and along the gap between the ends of the nanotubes the current flows thanks to the tunnel effect, which is a quantum phenomenon where electrons pass through a barrier that is considered insurmountable in classical mechanics.

This current is called tunneling current and is widely used in practice. There are, for example, tunnel diodes, wherein current flows through the potential barrier of the p-n junction.

Another example is a scanning tunneling microscope (STM), in which the surface of a sample is scanned with a very sharp needle under voltage. The needle slides along the surface, and the magnitude of the current flowing through it shows the distance to the sample with such accuracy that the STM can detect protrusions one atom high.

The authors of the article used the relationship between the tunneling current and the distance between the ends of the nanotubes to determine the relative position of the carbon nanotubes and thus to find the magnitude of the external force exerted on them.

The new sensor allows the position of coaxial cylinders in two-layer nanotubes to be controlled quite accurately. As a result, it is possible to determine the stretch of an n-scale object, to which electrodes are attached. Calculations made by the researchers showed the possibility of recording forces of a few tenths of a nN( 10-10 newtons). To make it clearer, a single bacterium weighs about 10-14 newtons on average, and a mosquito weighs a few dozen mcN (10-5 N).However, the device developed by the physicists may find application beyond micro scales.

A double-layered coaxial nanotube is akin to a microscopic cylinder with a sliding piston. Such a system has already been considered by a number of other researchers as a potential part for various types of nanomachines. Nanotubes have been proposed for the role of micromanipulators, or connecting "studs" for complex mechanisms, and they may even be used for data storage; the position of the inner "piston" may encode one bit of information or more.

Furthermore, calculations have shown that it is possible to create a combined device, where inside a two-layer carbon nanotube there will be magnetic fullerenes. When placed in a magnetic field, a power will emerge, which could be measured by changes in the magnitude of tunneling current. This will convert the force sensor into a magnetic field sensor.

Other news from the department science

Most read news

More news from our other portals

See the theme worlds for related content

Topic world Sensor technology

Sensor technology has revolutionized the chemical industry by providing accurate, timely and reliable data across a wide range of processes. From monitoring critical parameters in production lines to early detection of potential malfunctions or hazards, sensors are the silent sentinels that ensure quality, efficiency and safety.

Topic world Sensor technology

Sensor technology has revolutionized the chemical industry by providing accurate, timely and reliable data across a wide range of processes. From monitoring critical parameters in production lines to early detection of potential malfunctions or hazards, sensors are the silent sentinels that ensure quality, efficiency and safety.