Bayer MaterialScience: With powerful research to independence

Materials manufacturer Bayer MaterialScience is concentrating intently on innovation and sustainability as it prepares for its planned independence. Richard Northcote, a member of the company’s Executive Committee, said on Monday in Leverkusen that these two factors are key drivers for continued commercial success. Bayer MaterialScience will continue to bring innovative products and solutions with sustainablity effects to market in the future, thus helping to master global challenges such as climate change, the growth of cities and increasing mobility.

Northcote emphasized that besides the well-stocked innovation pipeline, Bayer MaterialScience also boasts a clear and comprehensive focus on sustainability. All activities will be aligned on improving people’s lives, helping to preserve the environment and conserve natural resources, and creating value. “People, Planet, Profit – we are pursuing this approach rigorously and with increasing intensity,” said Northcote. The task is to anchor this throughout the company. “We intend to and will live sustainability everywhere at Bayer MaterialScience.”

Over 1,000 researchers and developers

Another key to future success is the company’s power to innovate, as Bayer MaterialScience Head of Innovation Dr. Ulrich Liman underscored. “Systematic innovation management helps us to select the most promising from the multitude of ideas and to then manage the corresponding projects efficiently and with a focus on success.” Roughly 1,200 employees are entrusted with research and development tasks at the company worldwide. Major innovation centers include Leverkusen, Germany; Shanghai, China; and Pittsburgh, U.S.A. “This regional structure with short, direct lines to the various markets and customers helps us in particular to recognize where exactly there is a need for innovative materials and application solutions.”

Decorative auto parts in one step

One current innovation from Bayer MaterialScience is a product that improves wind turbines and thus can contribute to the wider adoption of renewable energies. The product is a polyurethane-based infusion resin that increases the efficiency of rotor blades and shortens their production time. For the automotive industry, the company has developed DirectCoating/DirectSkinning technology – a process with which high-quality plastic components for automotive interiors can be produced and coated with a premium decorative finish in a single step.

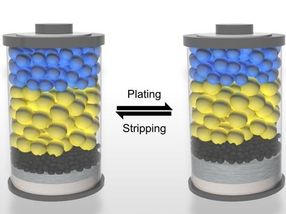

Producing plastics from CO2

In the field of development, Bayer MaterialScience has posted a number of new successes, including with its research into carbon dioxide as a new raw material for making plastics. In laboratory tests, the company has succeeded in once again significantly reducing the need for petroleum at the precursor level through the incorporation of CO2. To be specific, the Dream Polymers project is dedicated to a novel component (polyoxymethylene polycarbonate polyol) that now has an alternative raw material content of 40 percent. One of its uses is for the production of thermoplastic polyurethanes, which are required for such things as ski boots.

Most read news

Other news from the department business & finance

Get the chemical industry in your inbox

From now on, don't miss a thing: Our newsletter for the chemical industry, analytics, lab technology and process engineering brings you up to date every Tuesday and Thursday. The latest industry news, product highlights and innovations - compact and easy to understand in your inbox. Researched by us so you don't have to.