»Green Chemistry« ensures sustainable materials cycle

This year biobased processes and procedures and bio-economy are in the focus of ACHEMA, which will take place in Frankurt from June 15 to 19, 2015. The Fraunhofer Institute for Silicate Research ISC in Würzburg has set itself the goal of developing innovative materials and processes for environmentally friendly production and recycling. The Fraunhofer ISC shows recent examples of its work at the joint booth of the Fraunhofer-Gesellschaft, booth D64, hall 9.2.

New multifunctional materials can save resources, costs, and energy while providing innovative applications. In addition to the use of environment-friendly materials, process-optimized, efficient production processes and the re-use of raw materials play equally important roles for a sustainable future. Materials, however, which cannot be re-used, should at least be biodegradable or recyclable.

Re-use not consume resources

This is the motto of the Fraunhofer project group for material cycles and resource strategy IWKS headquartered in Alzenau/Hanau. The project group IWKS explores new recycling and substitution possibilities for rare and critical materials. Together with industry partners new technologies for the recovery and sorting of recyclable materials are being developed.

At ACHEMA, the project group IWKS presents latest developments in the field of biomaterials, which are in fact biowaste, but can serve different purposes as vegetable raw materials. One goal is to ensure that the acreage for renewable resources – often used as substitutes for petroleum-based materials – does not compete with the acreage for food. The use of biowaste materials from groceries and pharmaceutical industries could reduce costs and contributes to a more sustainable production, e.g. as base material in barrier layers for food packaging.

Self-recycling packaging

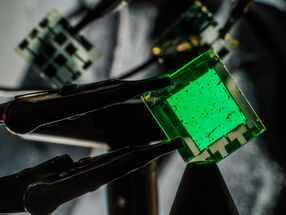

Researchers of the European project »DibbioPack« – short for »development of injection and blow extrusion molded biodegradable and multifunctional packages by nanotechnology« search for an alternative to commonly used petroleum-based plastic packaging. Within the project the Fraunhofer ISC developed novel biodegradable functional layers, so-called bioORMOCER®s that can be applied as a lacquer to films and other substrates. The bioORMOCER® barrier protects the contents from oxygen, water vapor, aromas or chemical substances, or in reverse doesn’t let them escape. So far, the barrier effect of conventional biodegradable materials was not sufficient. The novel bioORMOCER®s from biopolymers such as cellulose and chitosan decompose after only six weeks in certain formulations. However, the degradation rate can be adjusted to desired packaging properties, depending on whether pharmaceuticals, cosmetics or foods are packed.

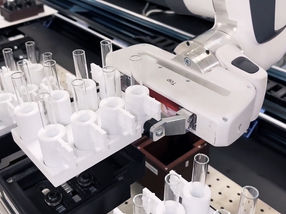

Smart process optimization – 100% quality control

Besides using ecologically harmless materials a sustainable production process is another important factor. SmartQCC – developed at the Center of Device Development CeDeD in Bronnbach Branch of Fraunhofer ISC – is suitable for the semi-automatic quality control of volumetric laboratory glassware such as pipettes and burettes. It enables easy and precise quality tests of measurement volumes by joystick. During the expo attendees are invited to give it a try at the booth of Fraunhofer ISC. Manual tests are complicated and give poorly reproducible results due to various sources of error. On the other hand, smartQCC offers high accuracy and repeatability with a precise detection of the markings and a direct printout of the measured values. Low maintenance and running costs complete the optimization of the manufacturing process of volumetric laboratory glassware.

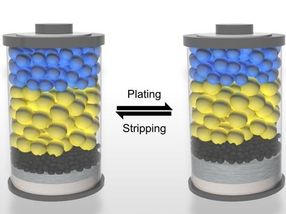

Wastewater treatment with magnetic particles

Many fertilisers, heavy metals and other substances end up in sewage and are difficult to remove. A development of the Fraunhofer ISC and the project group IWKS offers a remedy. Small, advanced magnetic particles that are distributed to the wastewater, can chemically bind polluting or other substances. With a magnet the loaded particles can be pulled out of the water, and the bonded substances can then be separated. As the method works very selectively, even very low concentrations of materials can be recovered with high purity. Afterwards both the particles and the materials are available for further use. For his discovery Dr. Karl-Sebastian Mandel was awarded the prestigious German Students Award of the Körber Foundation.

Most read news

Other news from the department science

Get the chemical industry in your inbox

From now on, don't miss a thing: Our newsletter for the chemical industry, analytics, lab technology and process engineering brings you up to date every Tuesday and Thursday. The latest industry news, product highlights and innovations - compact and easy to understand in your inbox. Researched by us so you don't have to.