Diamond detectors for CERN

A research team of Tomsk Polytechnic University is participating in the upgrade of the Large Hadron Collider (LHC) at the European Center for Nuclear Research (CERN). In the upgrading works TPU scientists were set the task to analyze operating detectors and to develop more reliable next generation diamond detectors. These detectors will record collision of elementary particles accelerating to the velocities close to light speed. The collisions occur every 28 nanoseconds.

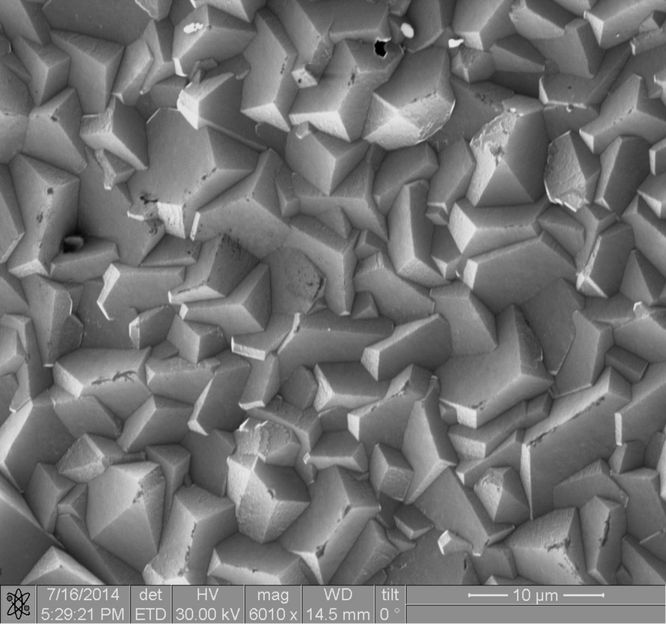

Photomicrograph of a polycrystalline diamond film is shown.

Tomsk Polytechnic University

'Energies that arise during the experiments at the Large Hadron Collider are the highest in the world. The conditions of the experiments are also unusual - the collisions of particles occur every 28 nanoseconds.

Accordingly, we need reliable and the most accurate detectors which provide fast responses to these collisions and are able quickly restore, ' points Professor Pavel Karataev, Royal Holloway University (UK), Head of the Electromagnetic Radiation Laboratory, RASA Center at TPU and one of the supervisor of TPU group at CERN.

In CERN the research team is part of BRIL project (Beam Radiation Instrumentation and Luminosity) of the CMS experiment, which is responsible for measuring: luminosity, machine induced background (MIB) and beam timing.

In the framework of BRIL the scientists are working to improve the reliability of the existing system of BCML (Beam Condition Monitor Leakage) diamond sensors that ensure safety at LHC, as well as to test own detectors based on synthetic diamonds produced by the scientists of the TPU Institute of High Technology Physics.

According to Pavel Karataev, in the short run, in order to continue experiments at the Large Hadron Collider scientists are going to enhance the intensity of proton beam by a factor of 10. If to do it right now, sensors that are not prepared for such loads, recording particle collisions and measuring luminosity of the beam in a close proximity to it, will stop functioning.

For this purpose TPU scientists have already measured all the detectors that are currently operate at CERN.

'Now we are irradiating them with particles. We will irradiate the detectors two months at different loads of applied voltage and radiation to determine an individual operating voltage for each detector, predict the wear rate, an average service life at certain capacities and other parameters,' clarifies Vitaly Okhotnikov, a research engineer at the Laboratory ?1, who supervises BCML project at CERN.

We also set ourselves an objective to develop detectors based on synthetic diamonds and produce them at TPU. They will feature more predictable wear resistance and, most importantly, their operating parameters will be predictable too.'

In addition, TPU scientists take part in the upgrade of the safety system of BCML CERN. The system automatically turns off accelerators of LHC when sensors record the excessive level of luminosity and radiation. After its upgrade, it will be easier to replace inappropriate sensors and as less as possible interact with emitting radiation.

Other news from the department research and development

Most read news

More news from our other portals

See the theme worlds for related content

Topic world Sensor technology

Sensor technology has revolutionized the chemical industry by providing accurate, timely and reliable data across a wide range of processes. From monitoring critical parameters in production lines to early detection of potential malfunctions or hazards, sensors are the silent sentinels that ensure quality, efficiency and safety.

Topic world Sensor technology

Sensor technology has revolutionized the chemical industry by providing accurate, timely and reliable data across a wide range of processes. From monitoring critical parameters in production lines to early detection of potential malfunctions or hazards, sensors are the silent sentinels that ensure quality, efficiency and safety.