Neither shaken nor stirred: A novel high rate system for biogas production from energy crops

A novel up-flow leach-bed process was developed by Leibniz Institute for Agricultural Engineering Potsdam-Bornim (ATB). It allows higher reactor loading rates, consumes less energy, is considerably less sensitive to overloading and, thus, increases economic efficiency of biogas production from energy crops.

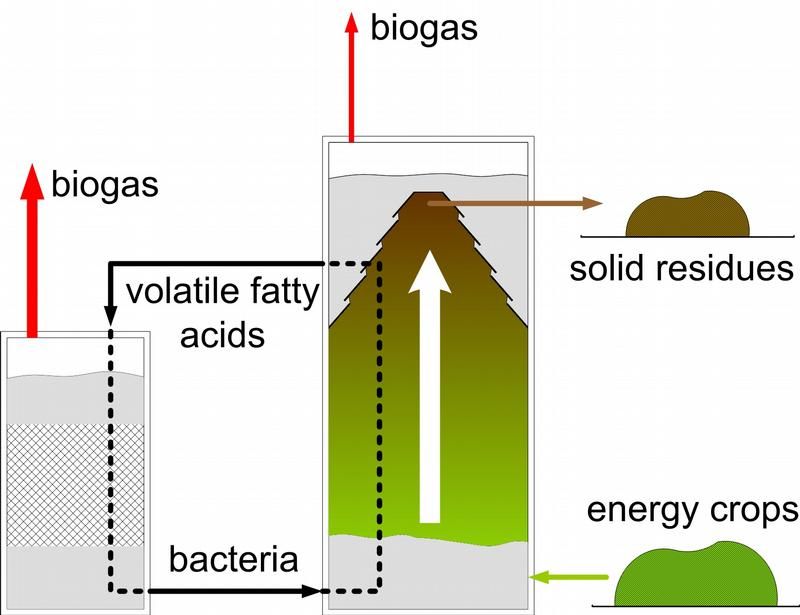

Two stage process: Up-flow anaerobic leach-bed reactor (right) with leachate circulation and high rate anaerobic reactor (left).

Jan Mumme

Farm-based biogas digesters of today are generally designed for the fermentation of liquid manure. Their use for energy crops is questionable, since these fibre-rich materials tend to build up a persistent float layer. In order to prevent flotation, agitation has to be intensified to a level, where it demands up to 10% of the electric energy produced.

The new up-flow leach-bed process developed by the Leibniz Institute for Agricultural Engineering follows a completely different strategy by stimulating flotation in order to increase not only energy efficiency but biogas production rates as well.

Key component of this two stage process is a novel anaerobic leach-bed reactor. Plant raw material is continuously fed to the reactor bottom and, after fermentation, removed from the top as solid residue. Gas bubbles generated by bacteria adhere to plant particles and thus, naturally induce floatation like in common digesters. Due to missing agitation inside the leach-bed reactor a liquid phase is formed and used as leachate. This leachate circulates upwards through the leach-bed reactor and downwards through a high rate anaerobic digester with immobilised bacteria. Volatile fatty acids are leached from the solids and efficiently converted to biogas in the high rate reactor. Excess bacteria are transferred to the leach-bed reactor enhancing solid degradation as well.

Experiments at laboratory scale reveal that compared with common farm-based digesters the reactor loading can be increased by at least factor two to three while yielding the same amount of gas. At significantly reduced energy demands the up-flow leach-bed process promises considerably increased productivity and stability as well as an uncomplicated and precise process control. The risk of overloading is practically eliminated. As a next step testing of this patent pending system at pilot-scale (10 m³) is projected.

Most read news

Organizations

Other news from the department research and development

Get the chemical industry in your inbox

From now on, don't miss a thing: Our newsletter for the chemical industry, analytics, lab technology and process engineering brings you up to date every Tuesday and Thursday. The latest industry news, product highlights and innovations - compact and easy to understand in your inbox. Researched by us so you don't have to.