Topic World Particle Analysis

Particle analysis methods allow us to study tiny particles in various materials and reveal their properties. Whether in environmental monitoring, nanotechnology or the pharmaceutical industry, particle analysis gives us a glimpse into a hidden world where we can decipher the composition, size and shape of particles. Experience the fascinating world of particle analysis!

Particle analysis products and catalogs

Particle analysis products

Particle analysis catalogs

Particle analysis brochures

Particle analysis news

Particle analysis expert knowledge

Particle analysis white papers

Particle analysis webinars

Particle analysis videos

Particle analysis explained

Determine particle size distribution

How to determine particle size distribution in polydisperse systems ...

View articleParticle size general

Particle size general Particle size is a notion introduced for comparing dimension of various small material object s. Larger objects are usually called stone, rock, a piece of something, etc. Term particle indicates small size, usually less than centimeter . Particle might be either solid , ...

View articleParticle size grain size

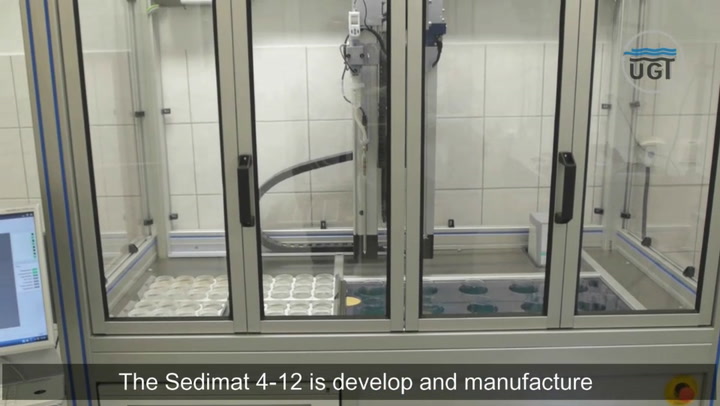

Particle size grain size Particle size, also called grain size, refers to the diameter of individual grains of sediment , or the lithified particles in clastic rock s. The term may also be applied to other granular material s. This is different from the crystallite size, which is the size o ...

View articleParticle size distribution

Particle size distribution The particle size distribution ("PSD") of a powder, or granular material, or particles dispersed in fluid, is a list of values or a mathematical function that defines the relative amounts of particles present, sorted according to size. PSD is also known as Grain size dist ...

View articleParticle sizes analysis methods

Why quality control in manufacturing and research is often based on particle size analysis ...

View article© 1997-2024 LUMITOS AG, All rights reserved