Henkel: New Research Center in Japan

The Henkel Group and Kinki University in Japan officially opened the Henkel Kindai laboratories - Research Center of Advanced Technology with an Opening Ceremony on 18th May 2001. The contract for the construction of the joint research center on the Kinki University campus in Iizuka, Kyushu was signed on 29th March 2000.

"This partnership between Kinki University and Henkel is the first of its kind in Japan. The University's highly positive response helped us establish the Henkel Kindai Laboratories so quickly" thanked Dr. Wolfgang Gawrisch, Corporate Vice President of Research and Technology at Henkel.

The cooperation is initially planned for 10 years. Henkel plans to invest approximately euro 25 million. For the new research center - a brand new building of 1400 square meters was constructed on the Kyushu School of Engineering site, part of Kinki University in Iizuka. First research activities commenced in April 2000 in leased laboratories. Kinki University supplied the plot and the infrastructure for the construction of the building. Along with the professors and scientists from Kinki University, visiting professors will be invited on a project-to-project basis to supervise the research. They will contribute their scientific expertise to the projects and will be involved as inventors in the research results. The directors of the research center are Prof. Emer. Toshihisa Maeshima, trustee of Kinki University and Prof. Takeshi Endo, professor at Yamagata University and former director of the Tokyo Institute of Technology.

The scientists at the Henkel Kindai Laboratories (40 post-docs and post-grads are planned) will initially work of the following main topics:

- New Microencapuslation Materials: Microencapsulation is a technology for protecting a substance from the surrounding environment. Smart and triggerable encapsulation materials are being developed which can protect the encapsulated substances so that they can be accurately delivered and released at a desired target. The mechanism and release time can be engineered as required. - Indicator Surfaces: The use of new technologies makes it possible to engineer smart surfaces with intelligent properties. Potential application areas include the automotive industry, hygiene, decorative cosmetics and product safety.

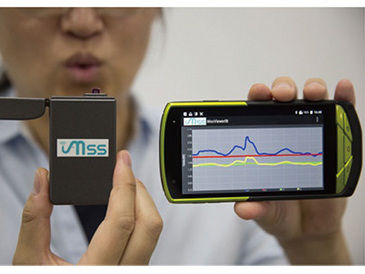

- New Sensors: Sensors are a fast growing modern technology. The development of miniature sensors makes it possible to identify even trace amounts of substances, e.g. hazardous substances or individual components in product mixtures. HKL are working on developing new materials for sensors with controllable selectivity for environment technologies, household and life-science applications.

- Advanced Polymer Systems: Classical methods of binding metallic substrates, such as welding and soldering, are increasingly being replaced by alternative bonding techniques. HKL are working on developing new high-performance polymer and adhesive systems for advanced applications.

Other news from the department

Most read news

More news from our other portals

See the theme worlds for related content

Topic world Sensor technology

Sensor technology has revolutionized the chemical industry by providing accurate, timely and reliable data across a wide range of processes. From monitoring critical parameters in production lines to early detection of potential malfunctions or hazards, sensors are the silent sentinels that ensure quality, efficiency and safety.

Topic world Sensor technology

Sensor technology has revolutionized the chemical industry by providing accurate, timely and reliable data across a wide range of processes. From monitoring critical parameters in production lines to early detection of potential malfunctions or hazards, sensors are the silent sentinels that ensure quality, efficiency and safety.