To use all functions of this page, please activate cookies in your browser.

my.chemeurope.com

With an accout for my.chemeurope.com you can always see everything at a glance – and you can configure your own website and individual newsletter.

- My watch list

- My saved searches

- My saved topics

- My newsletter

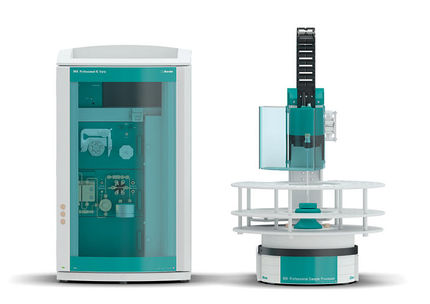

MicroemulsionMicroemulsions are clear, stable, isotropic liquid mixtures of oil, water and surfactant, frequently in combination with a cosurfactant. The aqueous phase may contain salt(s) and/or other ingredients, and the "oil" may actually be a complex mixture of different hydrocarbons and olefins. In contrast to ordinary emulsions, microemulsions form upon simple mixing of the components and do not require the high shear conditions generally used in the formation of ordinary emulsions. The two basic types of microemulsions are direct (oil dispersed in water, o/w) and reversed (water dispersed in oil, w/o). In ternary systems such as microemulsions, where two immiscible phases (water and ‘oil’) are present with a surfactant, the surfactant molecules may form a monolayer at the interface between the oil and water, with the hydrophobic tails of the surfactant molecules dissolved in the oil phase and the hydrophilic head groups in the aqueous phase. As in the binary systems (water/surfactant or oil/surfactant), self-assembled structures of different types can be formed, ranging, for example, from (inverted) spherical and cylindrical micelles to lamellar phases and bicontinuous microemulsions, which may coexist with predominantly oil or aqueous phases. Product highlight

UsesMicroemulsions have many commercially important uses. The fluid used in some dry cleaning processes is a water-in-oil microemulsion. Some floor polishes and cleaners, personal care products, pesticide formulations, and cutting oils are actually microemulsions. Much of the work done on these systems have been motivated by their possible use to mobilize petroleum trapped in porous sandstone for enhanced oil recovery. A fundamental reason for the uses of these systems is that a microemulsion phase sometimes has an ultralow interfacial tension with a separate oil or aqueous phase, which may release or mobilize them from solid phases even in conditions of slow flow or low pressure gradients. TheoryVarious theories concerning microemulsion formation, stability and phase behavior have been proposed over the years. For example, one explanation for their thermodynamic stability is that the oil/water dispersion is stabilized by the surfactant present and their formation involves the elastic properties of the surfactant film at the oil/water interface, which involves as parameters, the curvature and the rigidity of the film. These parameters may have an assumed or measured pressure and/or temperature dependence (and/or the salinity of the aqueous phase), which may be used to infer the region of stability of the microemulsion, or to delineate the region where three coexisting phases occur, for example. Calculations of the interfacial tension of the microemulsion with a coexisting oil or aqueous phase are also often of special focus and may sometimes be used to guide their formulation. History and terminologyThe term microemulsion was first used by Jack H. Shulman, a professor of chemistry at Columbia University, in 1959. Alternative names for these systems are often used, such as transparent emulsion, swollen micelle, micellar solution, and solubilized oil. More confusingly still, the term microemulsion can refer to the single isotropic phase that is a mixture of oil, water and surfactant, or to one that is in equilibrium with coexisting predominantly oil and/or aqueous phases, or even to other non-isotropic phases. Phase DiagramsThree components are the basic requirement to form a microemulsion: an oil phase, an aqueous phase and a surfactant. If a cosurfactant is used, it may sometimes be represented at a fixed ratio to surfactant as a single component, and treated as a single "pseudo-component". The relative amounts of these three components can be represented in a ternary phase diagram. Gibbs phase diagrams can be used to show the influence of changes in the volume fractions of the different phases on the phase behavior of the system. The three components composing the system are each found at an apex of the triangle, where their corresponding volume fraction is 100%. Moving away from that corner reduces the volume fraction of that specific component and increases the volume fraction of one or both of the two other components. Each point within the triangle represents a possible composition of a mixture of the three components or pseudo-components, which may consist (ideally, according to the Gibbs' phase rule) of one, two or three phases. These points combine to form regions with boundaries between them, which represent the "phase behavior" of the system at constant temperature and pressure. References

Categories: Colloidal chemistry | Soft matter |

|

| This article is licensed under the GNU Free Documentation License. It uses material from the Wikipedia article "Microemulsion". A list of authors is available in Wikipedia. |