To use all functions of this page, please activate cookies in your browser.

my.chemeurope.com

With an accout for my.chemeurope.com you can always see everything at a glance – and you can configure your own website and individual newsletter.

- My watch list

- My saved searches

- My saved topics

- My newsletter

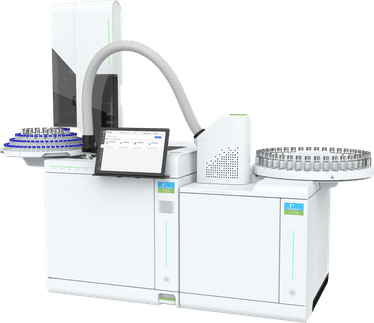

Plasma etcherFor the formation of integrated circuits it is necessary to structure various layers. This can be done by a Plasma etcher. Plasma etching of dielectrics, semiconductors and metals is state of the art today. Before etching, a photo resist is deposited on the surface, illuminated through a mask, and developed. The dry etch is then performed so that structured etching is achieved. After the process, the remaining photo resist has to be removed. This is also done in a special plasma etcher, called asher. Product highlightFor etching, the reactive gas is exited by a high frequent alternating electromagnetic field of 13.56 MHz in a low pressure environment resulting in the formation of reactive ions and radicals, called plasma. When the ions are accelerated towards the surface of the sample, anisotropic etching is achieved while the reaction of radicals with the sample results in isotropic etching. Dry etching allows a reproducible, uniform etching of all materials used in silicon and III-V-semiconductor technology. Plasma etchers are also used for delayering integrated circuits in failure analysis |

| This article is licensed under the GNU Free Documentation License. It uses material from the Wikipedia article "Plasma_etcher". A list of authors is available in Wikipedia. |