To use all functions of this page, please activate cookies in your browser.

my.chemeurope.com

With an accout for my.chemeurope.com you can always see everything at a glance – and you can configure your own website and individual newsletter.

- My watch list

- My saved searches

- My saved topics

- My newsletter

Polybrominated biphenyl

Polybrominated biphenyls (PBBs), also called brominated biphenyls or polybromobiphenyls, are a group of manufactured chemicals. While once widely used commercially, PBBs are now controlled substances under the Restriction of Hazardous Substances Directive, which limits their use in electrical and electronic products sold in the EU. Product highlight

CharacteristicsPBBs usually exist as colorless to off-white solids. Its notable characteristics include:

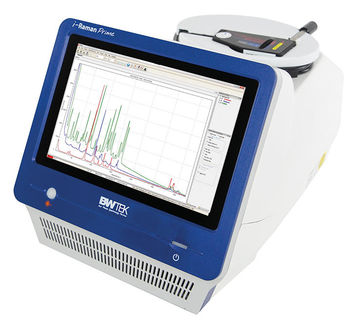

ApplicationPBBs are used as flame retardants of the brominated flame retardant group. They are added to plastics used in products such as home electrical appliances, textiles, plastic foams etc. to make them difficult to burn. Health hazardsMost of our knowledge about the effects of PBBs on human beings came from studies of people in Michigan, USA who consumed PBB-contaminated animal products (see history of PBBs below). Some residents complained of nausea, abdominal pain, loss of appetite, joint pain and lethargy, though it could not be clearly established that PBBs were the cause of these health problems. There is stronger evidence that PBBs may have caused skin problems, such as acne, in consumers of the contaminated food. Some workers exposed to PBBs by breathing and skin contact for days to months also developed acne. Studies in animals exposed to large amounts of PBBs for a short period or to smaller amounts over a longer period show that PBBs can cause weight loss, skin disorders, nervous and immune systems effects, as well as effects on the liver, kidneys, and thyroid gland. CarcinogenIt is not known for certain if PBBs could cause cancer in human beings, but it has been observed that they can lead to cancer in lab mice exposed to very high concentrations of PBBs. Based on such animal tests, the United States Department of Health and Human Services has determined that PBBs may reasonably be anticipated to be carcinogens. The International Agency for Research on Cancer also suggests that PBBs are possibly carcinogenic to humans. HistoryBefore the 1970s, PBBs were widely used commercially as a flame retardant. In 1973, however, several thousand pounds of PBBs were accidentally mixed with livestock feed that was distributed to farms in West Central Michigan, USA. Some 1.5 million chickens, 30,000 cattle, 5,900 pigs, and 1,470 sheep had become contaminated with PBBs before the error was discovered. These events were dramatized in the 1981 film Bitter Harvest. Although these animals were promptly culled, a study was undertaken on 4,545 people to determine the effects of PBBs on human beings. These include three exposure groups – all people who lived on the quarantined farms, people who received food from these farms and workers (and their families) engaged in PBB manufacture – as well as 725 people with low-level PBB exposure. All were queried concerning 17 symptoms and conditions possibly related to PBBs. Venous blood was drawn and analyzed for PBB by gas chromatography. Mean serum PBB levels were found to be 26.9 ppb by weight (26.9 µg/kg) in farm residents, 17.1 in recipients, 43.0 ppb in workers, and 3.4 ppb in the low exposure group. No associations could be established between serum PBB levels and symptom prevalence rates. To evaluate peripheral lymphocyte function, T and B cell quantitation and in vitro responses to three nonspecific mitogens were studied in 34 persons with highest PBB levels (mean: 787 ppb), and in 56 with low levels (mean: 2.8 ppb). Again, no statistically significant differences in lymphocyte function were noted. Noting the possible hazards on the environment, however, PBBs were listed as one of six controlled substances under the Restriction of Hazardous Substances Directive (ROHS), which was enacted into European Law in February 2003. ROHS legislation lists PBBs as a "restricted substance" group. Other countries followed suit, resulting most recently in restriction dates instituted in China on March 1, 2007 and South Korea on July 1, 2007. Testing for PBB in plasticsUntil recently testing for PBB has been cumbersome. Cycle time, inaccuracy, cost and level of expertise required for the test engineer has precluded the implementation of any screening of plastic component in a manufacturing or in a product qualification/validation environment. Recently, with the introduction of a new analytical instrument IA-Mass™, screening of plastic material alongside manufacturing line is possible. A 5 min. detection cycle and a 20 min. quantification cycle is available to test and to qualify plastic parts as they reach the assembly line. See also |

|

| This article is licensed under the GNU Free Documentation License. It uses material from the Wikipedia article "Polybrominated_biphenyl". A list of authors is available in Wikipedia. |