To use all functions of this page, please activate cookies in your browser.

my.chemeurope.com

With an accout for my.chemeurope.com you can always see everything at a glance – and you can configure your own website and individual newsletter.

- My watch list

- My saved searches

- My saved topics

- My newsletter

Vickers hardness test

The Vickers hardness test was developed in the early 1920s as an alternative method to measure the hardness of materials. The Vickers test is often easier to use than other hardness tests since the required calculations are independent of the size of the indenter, and the indenter can be used for all materials irrespective of hardness. The basic principle, as with all common measures of hardness, is to observe the questioned materials' ability to resist plastic deformation from a standard source. The Vickers test can be used for all metals and has one of the widest scales among hardness tests. The unit of hardness given by the test is known as the Vickers Pyramid Number (HV). The hardness number can be converted into units of Pa, but should not be confused with a pressure, which also has units of Pa. The hardness number is determined by the load over the surface area of the indentation and not the area normal to the force, and is therefore not a pressure. The hardness number is not really a true property of the material and is an empirical value that should be seen in conjunction with the experimental methods and hardness scale used. When doing the hardness tests the distance between indentations must be more than 2.5 indentation diameters apart to avoid interaction between the work-hardened regions. The yield strength of the material can be approximated as

where c is a constant determined by geometrical factors usually ranging between 2 and 4. Product highlight

Implementation

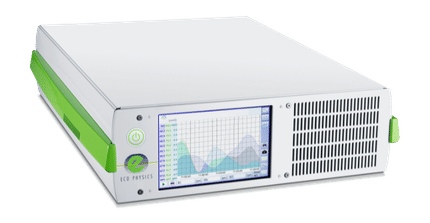

The Vickers hardness test uses a diamond, with the shape of square-based pyramid with an angle of 136° between opposite faces as an indenter (22° between the indenter face and surface). It is based on the principle that impressions made by this indenter are geometrically similar regardless of load. Accordingly, loads of various magnitudes are applied to a flat surface, depending on the hardness of the material to be measured. The Vickers Pyramid Number (HV) is then determined by the ratio F/A where F is the force applied to the diamond and A is the surface area of the resulting indentation. A can be determined by the formula

which can be approximated by evaluating the sine term to give

where d is the average length of the diagonal left by the indenter. Hence,

The corresponding units of HV are then kilogram-force per square millimetre (kgf/mm²). To convert a Vickers hardness number in SI units (MPa or GPa) one needs to convert the force applied from kgf to newtons and the area from mm2 to m2 to give results in pascals (1 kgf/mm² = 9.80665×106 Pa). A practical method to convert HV to SI units: To convert HV to MPa multiply by 9.807

To convert HV to GPa multiply by 0.009807 Vickers hardness numbers are reported as xxxHVyy, e.g. 440HV30, where:

ExamplesSome HV values[1]

References

See also |

|

| This article is licensed under the GNU Free Documentation License. It uses material from the Wikipedia article "Vickers_hardness_test". A list of authors is available in Wikipedia. |

.

.

,

,

,

,

.

.