'Invulnerable' coatings for cutting tools from gas

Scientists from Tomsk Polytechnic University (TPU) create coverings for next generation cutting tools: they will be not only durable, but also suitable for the treatment of most materials. Polytechnicers develop a technology to produce diamond and cubic boron nitride thin films from a gas mixture.

Diamond coatings due to their hardness have been widely used in the manufacture of cutting tools. They are used for the treatment of some metal alloys, ceramics, carbon composites, but ineffective for the iron and steel: at high temperature carbon interacts with these metals and gradually collapses.

To resolve this problem, TPU scientists proposed to develop a composite coating based on diamond and cubic boron nitride. It is the hardest known material.

Cubic boron nitride is not destroyed by contact with iron and steel, which makes a tool almost "invulnerable".

"Nobody has synthesized cubic boron nitride coatings in the form of polycrystalline carbon yet. We want to use the crystal lattice proximity of the substance and diamond. This similarity allows growing cubic boron nitride crystals on diamond crystals.

Our coating that integrates the properties of diamond and nitride coatings, will be applicable to most metals,"

- explains Stepan Linnik, a research engineer from the laboratory Nr.1, the TPU Institute of High Technology Physics.

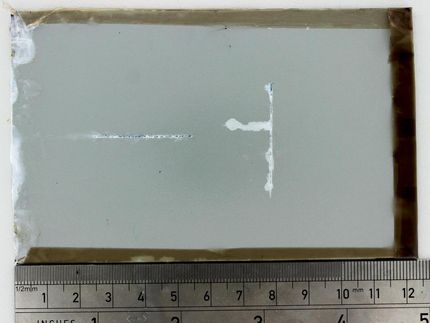

The scientists of Tomsk Polytechnic University obtain coverings from gas by means of plasma. The university has already developed a diamond sputtering technology from a mixture of methane and hydrogen. Cubic boron nitride will be also obtained from gas: a source material will serve diborane. Thus, the scientists will be able to cover a carbide tool with thin films, increasing its strength at times.

Original publication

Other news from the department science

Get the chemical industry in your inbox

From now on, don't miss a thing: Our newsletter for the chemical industry, analytics, lab technology and process engineering brings you up to date every Tuesday and Thursday. The latest industry news, product highlights and innovations - compact and easy to understand in your inbox. Researched by us so you don't have to.