To use all functions of this page, please activate cookies in your browser.

my.chemeurope.com

With an accout for my.chemeurope.com you can always see everything at a glance – and you can configure your own website and individual newsletter.

- My watch list

- My saved searches

- My saved topics

- My newsletter

Pulse tube refrigeratorThe Pulse tube cryocooler is a developing technology that emerged largely in the early 1980's with a series of other innovations in the broader field of Thermoacoustics. In contrast with other cryocoolers (eg Stirling cryocooler and Gifford-McMahon cooler), this cryocooler can be made without moving parts in the low temperature part of the device. The lack of moving parts makes the cooler suitable for a wide variety of applications. Product highlight

UsesPulse Tube Cryocoolers have been used in industrial applications such as semiconductor fabrication and in military applications such as for the cooling of infrared sensors.[1] Pulse tubes are also being developed for cooling of astronomical detectors where liquid cryogens are typically used, such as the Atacama Cosmology Telescope.[2] Pulse tubes will be particular useful in space-based telescopes where it is not possible to replenish the cryogens as they are depleted. It has also been suggested that pulse tubes could be used to liquefy oxygen on Mars.[3] The ice cream manufacturer Ben and Jerry's invested in a related thermoacoustic cooling technology, funding a pilot thermoacoustic ice-cream refrigerator project in New York City. The technology's environmentally clean alternative to chemicals used in conventional freezers is attractive to Ben and Jerry's. [4] DescriptionHere the so-called Stirling-type single-orifice pulse-tube refrigerator will be treated operating with an ideal gas (helium) as the working fluid. Figure 1 represents the Stirling-type single-orifice Pulse-Tube Refrigerator (PTR). From left to right the components are:

The part in between X1 and X3 is thermally insulated from the surroundings, usually by vacuum. The cooler is filled with helium at a pressure in the range from 10 to 30 bar. The pressure varies gradually and the velocities of the gas are low. So the name "pulse" tube cooler is very misleading since there are no pulses whatsoever in the system. How it operatesThe piston moves periodically from left to right and back. As a result the gas also moves from left to right and back while the pressure goes up and down in the system. If the gas from the compressor space moves to the right it enters the regenerator with temperature TH and leaves the regenerator at the cold end with temperature TL, hence it gives off heat to the regenerator material. On its return it takes up this heat again. The performance of the cooler is determined mainly by the quality of the regenerator. It has to satisfy conflicting requirements: it must have a low flow resistance (so it must be short with wide channels), but the heat exchange should also be good (so it must be long with narrow channels). The material must have a large heat capacity. At temperatures above 50 K practically all materials are suitable. Bronze or stainless steel is often used. For temperatures between 10 and 50 K lead is most suitable. Below 10 K one uses magnetic materials which are specially developed for this application. The thermal environment of a gas element near X2, that moves back and forth in the system, changes when it passes the heat exchanger. In the regenerator and in the heat exchanger the heat contact between the gas and its surrounding material is good. Here the temperature of the gas is practically the same as of the surrounding medium. However, in the pulse tube the gas element is thermally isolated, so, in the pulse tube, the temperature of the gas element varies with the pressure.

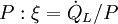

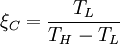

Look at figure 2 and concentrate on gas elements close to X3 (at the hot end) which move in and out the pulse tube. A gas element that flows into the tube does so when the pressure in the tube is low (it is sucked into the tube via X3 coming from the orifice and the buffer). At the moment it enters the tube it has the temperature TH . Later in the cycle it is pushed out the tube again when the pressure inside the tube is high. As a consequence its temperature will be higher than TH . In the heat exchanger X3 it releases heat and is cooles to the ambient temperature TH . At the cold end of the pulse tube there is the opposite effect: here gas elements enter the tube via X2 when the pressure is high with temperature TL and return when the pressure is low with a temperature below TL. They take up heat from X2 : this gives the desired cooling power! PerformanceThe so-called Coefficient Of Performance ξ (COP) of coolers is defined as the ratio between the cooling power

which is also called the Carnot COP. However, a pulse-tube refrigerator is not perfectly reversible due to the presence of the orifice which has flow resistance. Therefore equation (1) does not hold. Instead the COP of an ideal PTR is given by

Comparing relations 1 and 2 shows that the COP of PTR’s in lower than of ideal coolers indeed. Comparison with other coolersIn most coolers gas is compressed and expanded periodically. Well-known coolers as the Stirling coolers and the popular Gifford-McMahon coolers have a displacer that ensures that the cooling (due to expansion) takes place in a different region of the machine than the heating (due to compression). But, due its cleaver design, the PTR has not such a displacer. This means that the construction of a PTR is simpler, cheaper, and more reliable. Furthermore there are no mechanical vibrations and no electro-magnetic interferences. HistoryThe PTR is invented by Mikulin in 1984[5]. He reached a temperature of 105 K. Soon after that PTR’s became better due to the invention of new variations[6][7][8][9][10]. This is shown in figure 3 in which the lowest temperature for PTR’s is plotted as a function of time.

At the moment the lowest temperature is below the boiling point of helium (4,2 K). Originally this was considered to be impossible. For some time it looked as if it would be impossible to cool below the lambda point of 4He (2,17 K), but the Low-Temperature group of the Eindhoven University of Technology managed to cool to a temperature of 1,73 K by replacing the usual 4He as refrigerant by its rare isotope 3He. Later this record was broken by the Giessen Group that managed to get even below 1.3 K. In a collaboration between the groups from Giessen and Eindhoven a temperature of 1.2 K was reached by combining a PTR with a superfluid vortex cooler[11]. ProspectsThe COP of PTR’s at room temperature is low, so it is not likely that they will play a role in domestic cooling. However, below about 80 K the COP is comparable with other coolers (compare Eqs.(1) and (2)) and in the low-temperature region the advantages get the upper hand. For the 70K- and the 4K temperature regions PTR’s are commercially available. They are applied in infrared detection systems, for reduction of thermal noise in devices based on (high-Tc) superconductivity such as SQUID's, and filters for telecommunication. PTR’s are also suitable for cooling MRI-systems and energy related system using superconducting magnets. In so-called dry magnets coolers are used so that no cryoliquid is needed at all or for the recondensation of the evaporated helium. Also the combination of cryocoolers with ³He-4He dilution refrigerators for the temperature region down to 2 mK is attractive since in this way the whole temperature range from room temperature to 2 mK will be easier to access. See alsoReferences

|

|||||

| This article is licensed under the GNU Free Documentation License. It uses material from the Wikipedia article "Pulse_tube_refrigerator". A list of authors is available in Wikipedia. |

is delivered at the low temperature

is delivered at the low temperature  . For a perfectly reversible cooler

. For a perfectly reversible cooler

.

.