To use all functions of this page, please activate cookies in your browser.

my.chemeurope.com

With an accout for my.chemeurope.com you can always see everything at a glance – and you can configure your own website and individual newsletter.

- My watch list

- My saved searches

- My saved topics

- My newsletter

Water meterA water meter is a device used to measure the volume of water usage. This article provides an overview of technical aspects of water meters. The worldwide prevalence of metering as well as its economic benefits and costs are covered in the separate article on water metering. In many developed countries, water meters are used at each residential and commercial building in a public water supply system. Water meters can also be used at the water source, well, or throughout a water system to determine flow through that portion of the system. Water meters typically measure and display total usage in cubic feet, cubic meters or US gallons on a mechanical or electronic register. There are several types of water meters in common use. Selection is based on different flow measurement methods, the type of end user, the required flow rates, and accuracy requirements. In North America, standards for manufacturing of water meters are made by the American Water Works Association. There are three common methods of flow measurement in use: Common types of water meters

In addition to the more common types of meter, there are meters designed for special uses. Most meters in a typical water distribution system are designed for cold potable water only. There are specialty water meters manufactured for specific other uses. Hot water meters are designed with special materials that can withstand higher temperatures. Meters for reclaimed water, have special lavender register covers to signify the water is non-potable and should not be used for drinking. Water meters are generally owned, read, and maintained by a public water provider such as a city, rural water association, or private water company. In some cases an owner of a mobile home park, apartment complex or commercial building may be billed by a utility on one meter, and want to share the cost of the bill among the tenants. In this case, private meters may be purchased to separately track usage of each unit in what is called submetering. Product highlight

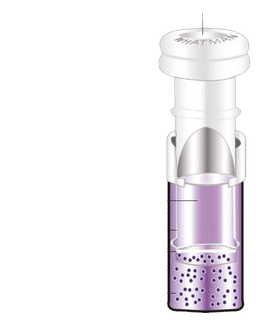

Displacement water metersThis type of water meter is most often used in residential and small commercial applications. Displacement meters are commonly referred to as Positive Displacement, or "PD" meters. Two common methods of positive displacement measuring are Oscillating Piston meters and Nutating Disk meters. Either method relies on the water to physically displace the moving measuring element in direct relation to the amount of water that passes through the meter. The piston or disk moves a magnet that drives the register. PD meters are generally very accurate at low to moderate flow rates typical of residential and small commercial users, and are common in sizes from 5/8" to 2". Because displacement meters rely on all flowing through the meter to "push" the measuring element, they generally are not practical in large commercial applications requiring high flow rates or low pressure loss. PD meters normally have a built in strainer to protect the measuring element from rocks or other debris that could stop or break the measuring element. PD meters normally have bronze, brass or plastic bodies with internal measuring chambers made from molded plastics and stainless steel. Velocity water metersA velocity type meter measures the velocity of flow though a meter of a known internal capacity. The speed of the flow can then be converted into volume of flow for usage. There are a number of types of meters that measure water flow velocity to determine totalized usage. They include jet meters (single-jet and multi-jet), turbine meters, propeller meters, and mag meters. Most velocity based meters have an adjustment vane for calibration of the meter to required accuracy standards. Multi-jet metersMulti-jet meters are very accurate in small sizes and are commonly used in 5/8" through 2" sizes for residential and smaller commercial uses. Multi-jet meters use multiple ports surrounding an internal chamber to create a jet of water against an impeller. The impeller rotation speed is in relation to the velocity of water flow. Multi-jets are very accurate at low flow rates, but are not used in larger sizes since they don't have the straight through flow path of turbine meters use for the high flow rates used in large pipe diameters. Multi-jet meters generally have an internal strainer element that can protect the jet ports from getting clogged. Multi-jet meters normally have bronze alloy bodies or outer casings with internal measuring parts made from modern thermoplastics and stainless steel. Turbine metersTurbine meters are less accurate than displacement and jet meters at low flow rates, but the measuring element does not occupy or severely restrict the entire path of flow. The flow direction is generally straight through the meter, allowing for higher flow rates, and less pressure loss than displacement type meters. They are the meter of choice for large commercial users, fire protection, and as master meters for the water distribution system. Strainers are generally required to be installed in front of the meter to protect the measuring element from gravel or other debris that could enter the water distribution system. Turbine meters are generally available for 1-1/2" to 12" or higher pipe sizes. Turbine meters bodies are commonly made of Bronze, cast Iron, or ductile iron. Internal turbine elements can be plastic or non-corrosive metal alloys.

Compound metersA compound meter is used where high flow rates are necessary, but at times there are smaller rates of flow that still need to be accurately measured. Compound meters have two measuring elements and a check valve to regulate flow between them. At high flow rates, water is normally diverted primarily or completely to the turbine part of the meter. When flow rates drop to where the turbine meter cannot measure accurately, a check valve closes to divert water to a smaller meter than can measure the lower flow rates accurately. The low flow meter is typically a multi-jet or PD meter. By adding the registration of the high and low meter registers, the utility has the total consumption through the meter. Advanced Metering InfrastructureThe next generation of technology designed to help utilities streamline operations is known as AMI (Advanced Metering Infrastructure). AMI systems typically involve a standard water meter, connected to a radio, which is often two-way. The most functional (and powerful) AMI system would be a fixed network, with two way communication. This eliminates the need for meter readers, and all the costs associated with them (wages, vehicle insurance, replacing reading equipment, as well as intangible costs related to estimated billing, and slow-responding customer service). A system like this will allow the utility to acquire reads from their headquarters, and they can update their reads on demand. There are also remote shutoff valves available, and real-time leak detection, all of which help improve a utility's bottom line. With real-time leak detection, leaks can be dealt with promptly, avoiding billing disputes associated with a leak detected months after it began (as is common with estimated billing, and quarterly reads). Note that the remote shut-off valves shouldn't be completely closed on delinquint accounts; water is needed to sustain life. It is recommended that the remote shut-off valves be partially closed on delinquint accounts, in order to reduce water pressure without denying flow entirely. Note that again, this frees up personnel that do not need to go into the field to perform a shutoff. These valves are particularly valuable in neighbourhoods with high turn-over (military housing, university towns, These networks are often designed as a "mesh" network. This means that the radio units connected to the meter do not need to be in radio range of what is known as the "collector" (device which collects the radio singals from nearby meters and routes this data to the utility's office). Radio signals from meters which are in moderately remote locations can be relayed by neighbouring radios until this data gets to the collector (and ultimately the office). These radio singals usually indicate a unique account number, water usage, as well as a series of "flags" (tamper, low battery, leaking, others) which help the water utility respond to any issues which may be developing with that particular account/customer. Electromagnetic metersMagnetic flow meters, commonly referred to as "mag meters" are technically a velocity type water meter, except that they use electromagnetic properties to determine the water flow velocity rather than mechanical means which jet and turbine meters use. Mag meters use the physics principal of Faraday's law of induction for measurement, and require AC or DC electricity from line or battery to operate the electromagnets. Since mag meters have no mechanical measuring element, they normally have the advantage of being able to measure flow in either direction, and use electronics for measuring and totalising the flow. Mag meters can also be useful for measuring untreated water, raw (untreated/unfiltered) water, and wastewater, since there is no mechanical measuring element to get clogged or damaged by debris flowing through the meter. Strainers are not required with mag meters, since there is no measuring element in the stream of flow that could be damaged. Stray electrical energy flowing through the flow tube can cause inaccurate readings, therefore most mag meters are installed with either grounding rings or grounding electrodes to insure this bypasses the electrodes inside the flow tube which are use to measure the flow. RegistersThere are several types of registers on water meters. A standard register normally has a dial similar to a clock with gradations around the perimeter to indicate water usage measured by the meter, as well as a set of odometer wheels similar to that in a car. Modern registers are normally driven by a magnetic coupling between a magnet in the measuring chamber attached to the measuring element, and another attached to the bottom of the register. Gears in the register convert the motion of the measuring element to the proper usage increment for display on the sweep hand and the odometer. Many registers also have a leak detector. This is a small visible disk or hand that is geared closer to the rotation speed of the drive magnet so that very small flows that would be visually undetectable on the regular sweep hand can be seen. With Automatic Meter Reading, manufacturers have developed pulse or encoder registers to produce electronic output for radio transmitters, reading storage devices, and data logging devices. Pulse meters send a digital or analog electronic pulse to a recording device. Encoder registers have an electronic means for an external device to interrogate the register for either the position of the odometer wheels or a stored electronic reading. Frequent transmissions of consumption can be used to give smart meter functionality. There are also some specialized types of registers such as LCD display instead of mechanical odometers, and registers to output data or pulses to a variety of recording and controller devices. For industrial applications, output is often 4-20mA analog, for the recording or control of different flow rates in addition to totalization.

How to read a water meterDifferent size meters may indicate a reading in different resolutions. One rotation of the sweep hand could be 10 gallons or 1000 gallons. If one rotation of the hand represents 10 gallons, the meter has a 10 gallon sweep. Normally the last number(s) of the odometer are non-rotating or printed. The position of the sweep hand represents and replaces these fixed zeros if trying to determine actual water use. If one rotation of the hand is 10 gallons, the sweep hand is on 7, and the odometer shows 123456 plus a fixed zero, the highest resolution reading would be 1,234,567 gallons. Many utilities bill only to the nearest 100 or 1000 gallons, and often only read the leftmost numbers. They would only read and bill using 1234 and rounding to 1,234,000 gallons based on a 1000 gallon billing resolution and the example above. The most common rounding for a particular size meter will often have different colored odometer wheels, the ones ignored being black, and the ones read being white. References

See also

Categories: Flow meters | Water technology |

|

| This article is licensed under the GNU Free Documentation License. It uses material from the Wikipedia article "Water_meter". A list of authors is available in Wikipedia. |