To use all functions of this page, please activate cookies in your browser.

my.chemeurope.com

With an accout for my.chemeurope.com you can always see everything at a glance – and you can configure your own website and individual newsletter.

- My watch list

- My saved searches

- My saved topics

- My newsletter

Dielectric elastomersDielectric elastomers (DEs) are smart material systems which produce large strains (up to 300%) and belong to the group of electroactive polymers (EAP). Based on their simple working principle dielectric elastomer actuators (DEA) transform electric energy directly into mechanical work. DE are lightweight, have a high elastic energy density and are investigated since the late 90’s. Many potential applications exist as prototypes. Every year in spring a SPIE conference takes place in San Diego where the newest research results concerning DEA are exchanged.

Product highlight

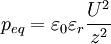

Working principleA DEA is a compliant capacitor (see image), where a passive elastomer film is sandwiched between two compliant electrodes. When a voltage U is applied, the electrostatic pressure pel arising from the Coulomb forces acting between the electrodes. Therefore the electrodes squeeze the elastomer film. The equivalent electromechanical pressure peq is twice the electrostatic pressure pel and is given by the following equation:  where MaterialsFor the elastomer often silicones and acrylic elastomers are used. In particular, the acrylic elastomer VHB 4910, commercially available from the company 3M has shown the largest activation strain (300%), a high elastic energy density and a high electrical breakdown strength. Basically, the requirements for an elastomer material for DEA are

A possibility to enhance the electrical breakdown strength is to prestretch the elastomer film mechanically. Further reasons for prestretching the elastomer are the following:

The elastomers show a visco-hyperelastic behavior. Models which describe large strains and viscoelasticity are required for the calculation of such actuators. Several different types of electrodes are used in the research (e.g. graphite powder, silicone oil / graphite mixtures, gold electrodes, etc.). The electrode should be conductive and compliant. The compliance of the electrode is important in order that the elastomer is not constrained mechanically in its elongation by the electrode. Configurations and applicationsSeveral configurations exist for dielectric elastomer actuators:

Current applications of this technology include Braille pads and carbon-elastomer active valves. Researchers have recently proposed the use of these elastomers as actuating devices for MEMS devices because at microscale thicknesses, the rise in energy density allows the electrostatic energy input to actuate the compression of the material to occur at far lower voltages. References"High-Speed Electrically Actuated Elastomers with Strain Greater Than 100%". Ron Pelrine, Roy Kornbluh, Qibing Pei, Jose Joseph. Science Vol. 287. no. 5454, pp. 836–839. 4 February 2000 [1] |

|

| This article is licensed under the GNU Free Documentation License. It uses material from the Wikipedia article "Dielectric_elastomers". A list of authors is available in Wikipedia. |

is the vacuum permittivity,

is the vacuum permittivity,  is the

is the