To use all functions of this page, please activate cookies in your browser.

my.chemeurope.com

With an accout for my.chemeurope.com you can always see everything at a glance – and you can configure your own website and individual newsletter.

- My watch list

- My saved searches

- My saved topics

- My newsletter

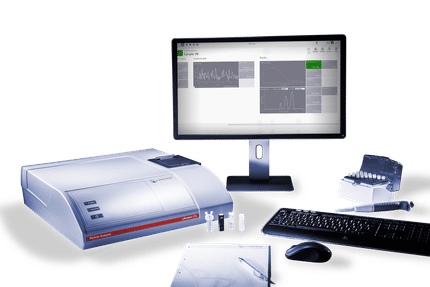

Energy-dispersive X-ray spectroscopyEnergy dispersive X-ray spectroscopy (EDS or EDX) is an analytical technique used predominantly for the elemental analysis or chemical characterization of a specimen. Being a type of spectroscopy, it relies on the investigation of a sample through interactions between electromagnetic radiation and matter, analyzing X-rays emited by the matter in this particular case. Its characterization capabilities are due in large part to the fundamental principle that each element of the periodic table has a unique atomic structure allowing x-rays that are characteristic of an element's atomic structure to be uniquely distinguished from each other. To stimulate the emission of characteristic x-rays from a specimen, an high energy beam of charged particles such as electrons or protons, or a beam of x-rays, is focused into the sample to be characterized. At rest, an atom within the sample contains ground state (or unexcited) electrons situated in discrete energy levels or electron shells bound to the nucleus. The incident beam may excite an electron in an inner shell, prompting its ejection and resulting in the formation of an electron hole within the atom’s electronic structure. An electron from an outer, higher-energy shell then fills the hole, and the difference in energy between the higher-energy shell and the lower energy shell is released in the form of an X-ray. The x-ray released by the electron is then detected and analyzed by the energy dispersive spectrometer. These x-rays are characteristic of the difference in energy between the two shells, and of the atomic structure of the element form which they were emitted. Product highlight

Technological VariantsThe excess energy of the electron that migrates to an inner shell (in order to fill the newly-created hole) can do more than emit an X-ray. Often, instead of X-ray emission, the excess energy is transferred to a third electron from a further outer shell, prompting its ejection. This ejected species is called an Auger electron, and the method for its analysis is known as Auger Electron Spectroscopy (AES). X-ray Photoelectron Spectroscopy (XPS) is another close relative of EDS, utilizing ejected electrons in a manner similar to that of AES. Information on the quantity and kinetic energy of ejected electrons is used to determine the binding energy of these now-liberated electrons, which is element-specific and hence allows chemical characterization of a sample. EDS is often contrasted with its microscale spectroscopic counterpart, WDS (Wavelength-Dispersive X-ray Spectroscopy). WDS differs from EDS in that it uses the diffraction patterns created by light-matter interaction as its raw data. WDS is much more precise than EDS, due to the phenomenon of peak overlap in EDS, where X-rays from various shells from different elements may have similar energies, making exact identification sometimes difficult. WDS avoids this problem, as each emitted X-ray wavelength is unique to that element. However, as WDS is a serial acquisition technique compared to the parallel acquisition in EDS, WDS spectra take significantly longer to acquire. EquipmentThere are four primary components of the EDS setup: the beam source; the X-ray detector; the pulse processor; and the analyzer. A number of free-standing EDS systems exist. However, EDS systems are most commonly found on scanning electron microscopes. Electron microscopes are equipped with a cathode and magnetic lenses to create and focus a beam of electrons, and since the 1960s they have been equipped with elemental analysis capabilities. A detector is used to convert X-ray energy into voltage signals; this information is sent to a pulse processor, which measures the signals and passes them onto an analyzer for data display and analysis. Emerging TechnologyThere is a trend towards a newer EDS detector, called the Silicon Drift Detector (SDD). The SDD consists of a high-resistivity silicon chip where electrons are driven to a small collecting anode. The advantage lies in the extremely low capacitance of this anode, thereby utilizing shorter processing times and allowing very high throughput. Benefits of the SDD include 1) High count rates and processing 2) Better resolution than traditional SiLi detectors at high count rates 3) Lower dead time (time spent on processing x-ray event) 4) Faster analytical capabilities and more precise X-ray maps or particle data collected in seconds and 5) Ability to be stored and operate at relatively high temperatures, eliminating the need for liquid nitrogen cooling. Because the capacitance of the SDD chip is independent of the active area of the detector, much larger SDD chips can be utilized (40mm sq. or more). This allows for even higher count rate collection. Further benefits of large area chips include 1) Minimizing SEM beam current allowing for optimization of imaging under analytical conditions 2) Reduced sample damage and 3) Smaller beam interaction and improved spatial resolution for high speed maps. In recent years a different type of EDS detector, based upon a microcalorimeter, has become commercially available. This new model allegedly has the simultaneous detection capabilities of EDS as well as the high spectral resolution of WDS. The EDS microcalorimeter relies highly on two components: an absorber, and a thermistor. The former absorbs X-rays emitted from the sample and converts this energy into heat; the latter measures the subsequent change in temperature due to the influx of heat (in essence, a thermometer). The EDS microcalorimeter has suffered from a number of drawbacks; including low count rates, poor collection efficiencies and small detector areas. The count rate is hampered by its reliance on the time constant of the calorimeter’s electrical circuit. The collection efficiency is a function of the absorber material and remains to be optimized. The detector area must be small in order to keep the heat capacity as small as possible and maximize thermal sensitivity (resolution). Innovative engineering solutions are necessary for further improvement of spectroscopic microanalysis. See also |

- EDAX EDS - EDAX EDS Systems

- Oxford Instruments EDS Systems - Oxford Instruments EDS Systems

- PANalytical XRF Spectrometers - EDXRF & WDXRF Spectrometers

- Thermo Scientific X-ray Microanalysis Spectral Imaging-based EDS

- Thermo Scientific NITON Analyzers - Portable NITON EDX from Thermo Scientific

- The Science of Spectroscopy - supported by NASA, includes OpenSpectrum, a Wiki-based learning tool for spectroscopy

- Cryogenic X-ray Microcalorimeters

- Microcalorimeter EDS With 3 eV Energy Resolution

- Princeton Gamma-Tech - Manufacturers of Energy Dispersive Spectrometers for Microanalysis

- eumeX Instrumentebau GmbH - Manufacturer of High-end Si(Li) detectors

- Mektech - Makers of URSA Next generation EDX Systems

- XIA, LLC - Manufacturer of State-of-the-Art Digital Spectrometers

- EDX/WDX Analysis - SiliconFarEast.com

- MICROANALYST.NET - Information portal with X-ray microanalysis and EDX contents

Categories: Spectroscopy | X-rays