To use all functions of this page, please activate cookies in your browser.

my.chemeurope.com

With an accout for my.chemeurope.com you can always see everything at a glance – and you can configure your own website and individual newsletter.

- My watch list

- My saved searches

- My saved topics

- My newsletter

INTA TechnologiesINTA Technologies (formerly International Technical Associates) of Santa Clara, California is a manufacturer and supplier of metallized ceramic products, coatings, glass to metal, glass to ceramic and other hermetic and non-hermetic seals and assemblies. INTA also provides precious metal and non-precious metal plating and brazing services. Founded in the 1970s, INTA began as a research and development group and now provides products to various industries including aerospace, defense, telecommunications, optics, sound, semiconductor, medical and diagnostic instrumentation. Product highlight

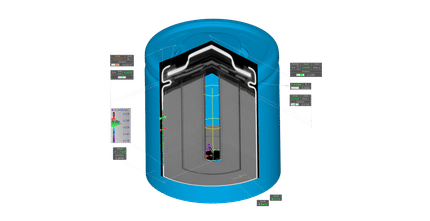

HistoryA group of scientists including Dr. Leonard Reed founded International Technical Associates in 1976 and for the next 25 years developed many of the proven technologies used in ceramic metallization and surface treatments. Much of the work was performed for government agencies and sensitive projects. Paul Lovoi led the company for many years and was involved in many projects and currently the chief engineers and scientists include Dr. Francis Honey, Dr. James Lynch and Dr. Nutan Bhiwandker. In 1999 International Technical Associates was purchased by a group of private investors and the name was changed to INTA Technologies. The company focused less on research and development instead turning to manufacturing, coating services and metallized ceramic products after 1999. INTA has roughly 30 employees and has close ties to Superior Technical Ceramics of St. Albans, VT and LFI Machining of Santa Clara. MetallizationMetallization is a process INTA employs wherein metallic conductive coatings are deposited and bonded to ceramics or other non-metallic substrates such as plastic, quartz and zirconia, for example. Depending on the specific material application a diffusion layer may be produced forming a very tight bond able to withstand mechanical and physical testing at relatively high temperatures. Precious metal coatingsINTA plates precious metals and other metals such as nickel and copper on substrates considered difficult to work with such as titanium and molybdenum along with tungsten (wolfram), copper tungsten, berrylium oxide and beryllia metal alloys. Various techniques are employed to guarantee superior adhesion and avoid pitting, discoloration and other problems such as peeling. Nickel plating is used widely in the transportation industry to protect metal parts from corrosion and make the components last longer without rusting. Ceramic productsCeramic products are growing in popularity due to rising costs for raw materials such as steel, cobalt, copper and other metals. Ceramics are often made from alumina which is a very common element and can be found on virtually every continent and country around the globe. Very little energy is needed to produce ceramic products compared to many other types of materials and ceramics have properties that make them attractive to industries such as electronics, microwave, defense, space and others. Ceramics come in many varieties and can be porous or non-porous. Ceramics are non-conductive but often can be metallized by use of pastes, paints or chemical processes. INTA produces metallized ceramic products which are often brazed to other types of material such as metal, glass or zirconia. Ceramics are popular in the medical industry because they do not react much with the human body and can withstand relatively harsh environments. Ceramics can be tape cast, injection molded, extruded or pressed depending on the specific application or intended use. Ceramics are very hard and therefore often green machining is desirable and diamond grinding is often required. ApplicationsCoatings are important because they can reduce costs and provide environmental (sustainable) benefits. Ceramic does not corrode in most cases but metal often does. Coatings play an important role in preventing or halting corrosion. For example, rather than producing a brand new metal part every year for use in an abrasive or harsh environment (chemical, marine or other), a coating can be used to provide durability, strength and wear resistance. Recycled materials are coated (i.e. plastics, aluminum, copper and steel. Many important medical devices need to be coated before they come in contact or are implanted into animals or humans. INTA manufactures and coats many such devices which are used in various applications and development projects including trauma recovery and diagnostics. The energy service industry uses high reliability products and services because a strong coating and/or bond is often needed due to harsh marine environments and extreme high/low temperature applications. See also

ReferencesINTA Technologies Website US3849877: Method For Making Conductors For Ferrite Memory Arrays Canadian Patent For Determining Whether Material Has Been Exposed To Temperatures Above A Predetermined Range Heckler, C. H., Jr.; Bhiwandker, N. C., "The results of the development and testing of ferrite monolithic memory arrays" NASA Center, 1972 Added to NTRS: 2004-11-03 Accession Number: 73N13238; Document ID: 19730004511; Report Number: NASA-CR-2152 Bhiwandker, N. C.; Heckler, C. H., Jr., "Magnetic logic batch fabrication techniques" NASA Center, 1970, Added to NTRS: 2004-11-03 Accession Number: 70N20476; Document ID: 19700011171; Report Number: NASA-CR-66890, RR-70-04 Nov. 1994 Paul Lovoi, "Laser Paint Stripping Offers Control and Flexibility," Laser Focus World, pp. 75-80 Ceramic Data Sheets (Material Properties) Categories: Coatings | Corrosion | Chemical processes | Dielectrics | Metal plating | Thin film deposition |

|

| This article is licensed under the GNU Free Documentation License. It uses material from the Wikipedia article "INTA_Technologies". A list of authors is available in Wikipedia. |