To use all functions of this page, please activate cookies in your browser.

my.chemeurope.com

With an accout for my.chemeurope.com you can always see everything at a glance – and you can configure your own website and individual newsletter.

- My watch list

- My saved searches

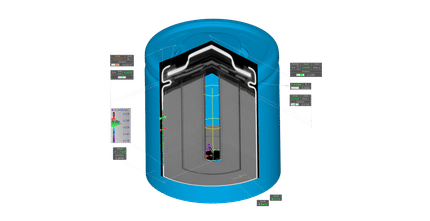

- My saved topics

- My newsletter

Silex ProcessSILEX is an acronym for Separation of Isotopes by Laser Excitation [1], a technology developed in the 1990s for isotope separation to produce enriched uranium using lasers. [2] Product highlightThe SILEX process was developed in Australia by Silex Systems Limited, a publicly listed high technology innovation company founded in 1988, and was invented by Dr Michael Goldsworthy and Dr Horst Struve.[3] In November 1996 Silex Systems Limited signed an exclusive license and development agreement for the application of SILEX technology to uranium enrichment with the United States Enrichment Corporation (USEC).[4] The company expected to conclude the second stage of testing in 2005 and begin building a pilot plant. The pilot plant will probably be built in the USA, giving effect to the 1996 agreement with USEC and avoiding any problems for Australia under the Nuclear Non-Proliferation Treaty. In 2004 Greenpeace produced a report on the political implications of SILEX process titled Secrets, Lies and Uranium Enrichment. [5] In 2006, Silex Systems limited signed a development agreement with US company General Electric as the sole developer of the technology. Details of the SILEX processAccording to Laser Focus World, the SILEX process exposes a cold stream of a mixture of uranium hexafluoride (UF6) molecules and a carrier gas to energy from a pulsed laser. The laser used is a CO2 laser operating at a wavelength of 10.8 μm (micrometres) and optically amplified to 16 μm, which is in the infrared spectrum. The amplification is achieved in a Raman conversion cell, a large vessel filled with high-pressure para-hydrogen. The 16 μm wavelength laser preferentially excites the 235UF6, creating a difference in the isotope ratios in a product stream, which is enriched in 235U, and a tailings stream, which has an increased fraction of the more common 238U. [6] The Sydney Morning Herald reports that "The lasers electrically charge the atoms, which become trapped in an electromagnetic field and drawn to a metal plate for collection."[7] According to John L. Lyman, the Silex Systems Ltd. (SSL) research facility in Australia uses a laser pulsed at a frequency of 50 Hz, a rate that results in great inefficiency. At 50 HZ, only 1% of the UF6 feedstock is processed. This results in a high fraction of feedstock entering the product stream and a low observed enrichment rates. Consequently, a working enrichment plant would have to substantially increase the laser duty cycle. In addition, the preparation time needed is prohibitively long for full-scale production. The SSL research facility requires ten hours of prep time for a one hour enrichment test run, significantly restricting output. [8] Further details of the technology, such as how it differs from the older molecular laser isotope separation(MLIS) and atomic vapor laser isotope separation (AVLIS) processes are not known publicly. The technique can be used for the isotopic enrichment of chlorine, molybdenum and uranium, and similar technologies can be used with carbon and silicon. [9] Security classification of SILEX informationSILEX is also distinctive in that it is currently the only privately-held information that is classified by the U.S. government. In June 2001, the U.S. Department of Energy classified "certain privately generated information concerning an innovative isotope separation process for enriching uranium." Under the Atomic Energy Act, all information not specifically declassified is classified as Restricted Data, whether it is privately or publicly held. This is in marked distinction to the national security classification executive order, which states that classification can only be assigned to information "owned by, produced by or for, or is under the control of the United States Government." This is the only known case of the Atomic Energy Act being used in such a manner. [10] [11] References

Categories: Atomic physics | Uranium |

| This article is licensed under the GNU Free Documentation License. It uses material from the Wikipedia article "Silex_Process". A list of authors is available in Wikipedia. |