Verder

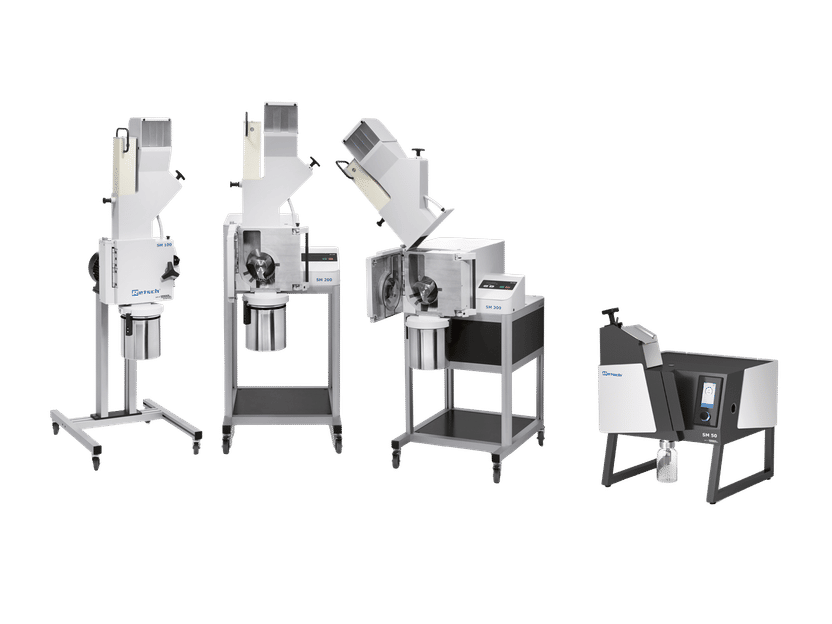

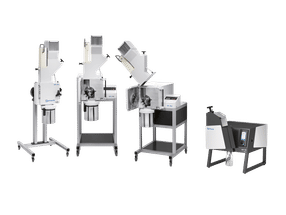

Cutting Mills

High-Performance grinding of heterogeneous materials with variable speed & defined fineness

Verder Scientific GmbH & Co. KG

Uncompromising cutting performance: thanks to high rotational energy and precise cutting geometry

Easy cleaning: for time-saving and contamination-free processes

Versatile: thanks to cyclone, various rotor types, tool materials, and hopper designs

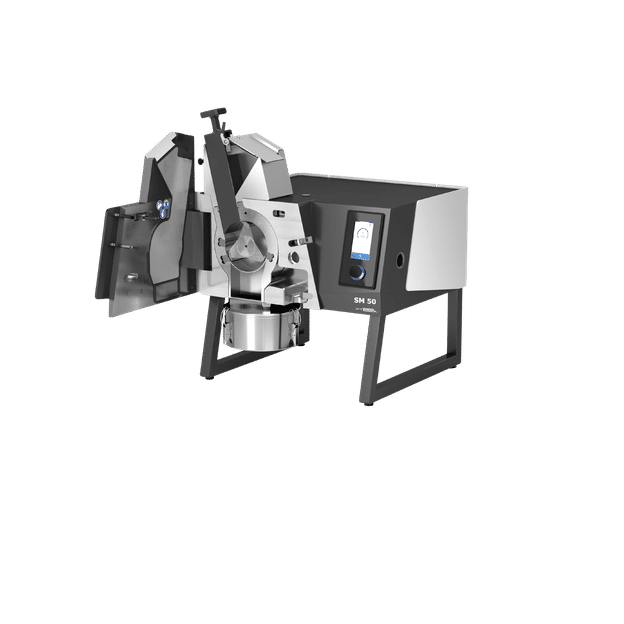

Powerful RES technology, easy cleaning, versatile for different setups with flexible accessories

RETSCH cutting mills are successfully used for the efficient pre-crushing of a wide range of materials. The devices offer maximum safety and ease of use. The extensive range of accessories allows the cutting mills to be quickly adapted to a wide variety of applications.

Your advantages:

- Powerful grinding – even of heterogeneous material mixtures

- Selection of different cutter mill models according to customer requirements

- Optimal cutting effect thanks to double-acting cutting beams (SM 200 & SM 300)

- SM 300 cutting mill with variable speed from 700 to 3,000 rpm, 3 kW drive with high torque

- Rotational energy storage technology (RES) ensures exceptional cutting power reserves (SM 300)

- Defined final fineness thanks to bottom screens with mesh sizes from 0.25–20 mm

- Low heat generation

- Quick and easy cleaning thanks to plug-in rotors, smooth surfaces, and hinged funnels (SM 200 and SM 300)

- Highest safety standard thanks to motor brake, central locking, and electronic safety monitoring

- Extensive range of accessories with various funnels, collection systems, rotors, and sieves

Cut-to-length grinder technology explained briefly:

- Grinding in cut-to-length grinders is achieved by cutting and shearing forces.

- The sample material enters the grinding chamber via the funnel, where it is picked up by the rotor and crushed between the rotor blades and the fixed cutting strips inserted in the housing.

- The sample material remains in the chamber for only a short time; as soon as it is small enough to fall through the openings in the bottom sieve, it is discharged and collected in the collection container.

1

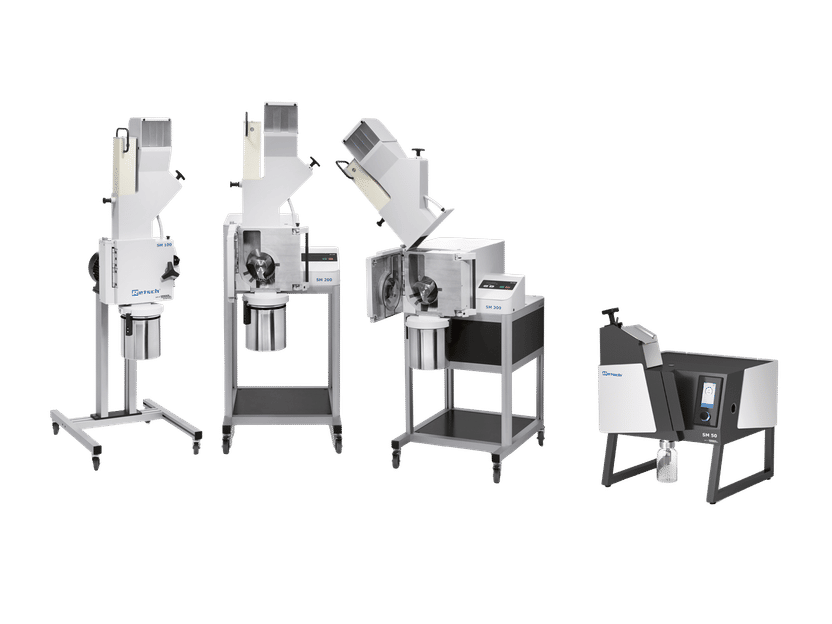

The RETSCH family of cutting mills

2

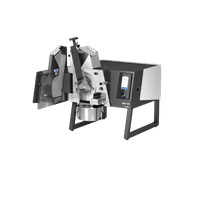

The new SM 50: the performance champion among benchtop cutting mills

3

SM 100 cutting mill – The affordable basic model

4

SM 200 cutting mill - The universal standard model

5

SM 300 cutting mill - The high-performance model with RES technology

Request information about Cutting Mills now

Cutting mills: Cutting Mills

High-Performance grinding of heterogeneous materials with variable speed & defined fineness

Product classification Cutting Mills

Product categories

Applications

Manufacturers of similar products

Advertisement

Find more cutting mills and related products

Find Cutting Mills and related products in the theme worlds

Topic World Battery Technology

The topic world Battery Technology combines relevant knowledge in a unique way. Here you will find everything about suppliers and their products, webinars, white papers, catalogs and brochures.

Topic World Battery Technology

The topic world Battery Technology combines relevant knowledge in a unique way. Here you will find everything about suppliers and their products, webinars, white papers, catalogs and brochures.