CARBOLITE - TS Split Tube Furnace

Innovative Heat Treatment for Electrodes: Advancing Sustainability in Battery Manufacturing

Verder Scientific GmbH & Co. KG

50% less energy consumption

Process optimization with programmable controllers

Lower external case temperatures enhance user safety and reduce energy consumption

Enhance battery sustainability and performance with precise, energy-efficient heat treatment

In today’s rapidly evolving battery industry, sustainable manufacturing practices are more important than ever for reducing environmental impact and ensuring the ongoing viability of energy storage technologies. With demand for advanced batteries accelerating in applications such as electric vehicles, renewable energy storage, and portable electronics, there is increasing pressure on manufacturers to adopt methods that are both highly efficient and environmentally responsible. One of the most impactful advancements in this pursuit is the heat treatment synthesis of electrodes using pyrolysis and sintering of precursor materials. This innovative process is reshaping battery production by not only boosting battery performance and reliability, but also by directly addressing key sustainability challenges inherent in the industry.

Sustainable Solution: Pyrolysis and Sintering

Precise and repeatable heat treatment processes create uniform layers of active battery materials, resulting in electrodes with consistent quality and structure. Pyrolysis and sintering effectively remove binders and solvents, leaving high-purity, stable materials. This uniformity is essential for high-performance batteries that meet strict safety and environmental standards.

Advanced Safety and Scalability

Programmable controllers and advanced gas handling allow safe operation under modified atmospheres or vacuum, preventing moisture and oxygen-related hazards and reducing fire or explosion risks. Modern furnace systems are scalable, from laboratory research to industrial-scale production, ensuring quality and safety at every stage.

Key Benefits:

- Up to 50% less energy consumption through advanced insulation and power management

- Reduced carbon footprint and improved sustainability

- Durable construction for long service life and minimal waste

- Lower external case temperatures for enhanced safety and comfort

- Consistent, uniform heating for high-quality electrode materials

- Improved material consistency, reduced waste, and higher yields

Enabling a Sustainable Future

Through these advanced heat treatment technologies, battery manufacturers can drive both innovation and environmental stewardship. The result is high-performance batteries with lower operational costs, reduced emissions, and strong support for a cleaner energy future.

1

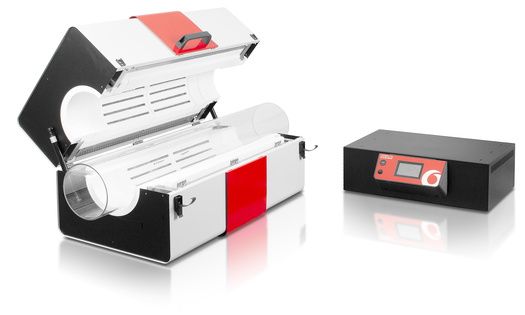

TS1-1200 with AriesPlus Controller

2

TS range

3

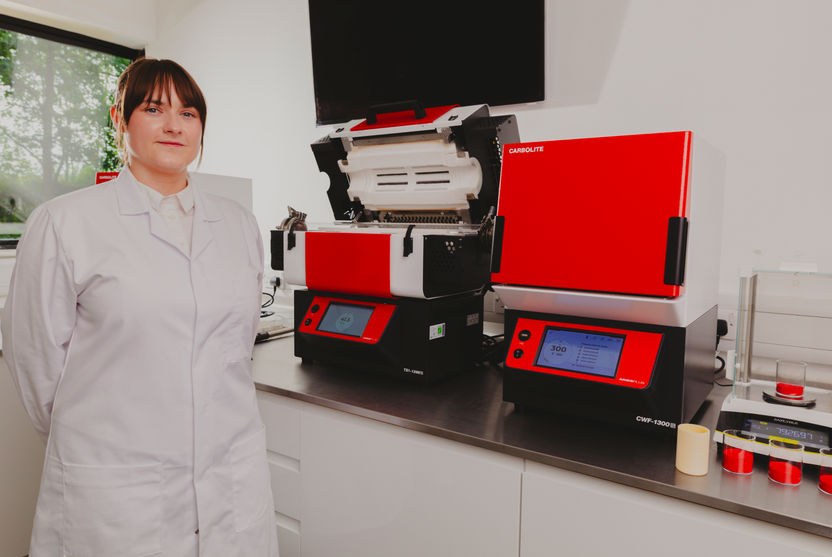

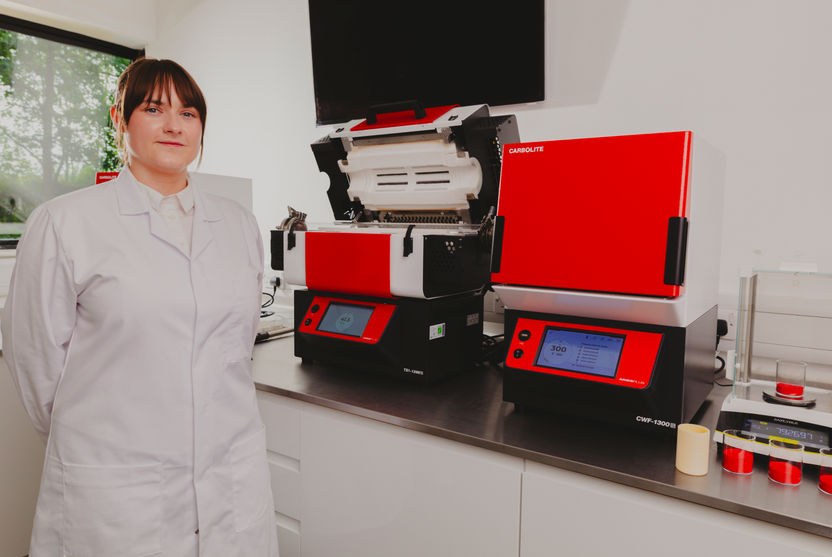

TS Furnace

4

TS Furnace

5

TS Furnace

Request information about CARBOLITE - TS Split Tube Furnace now

Split tube furnaces: CARBOLITE - TS Split Tube Furnace

Innovative Heat Treatment for Electrodes: Advancing Sustainability in Battery Manufacturing

Product classification CARBOLITE - TS Split Tube Furnace

Product categories

Applications

Advertisement