To use all functions of this page, please activate cookies in your browser.

my.chemeurope.com

With an accout for my.chemeurope.com you can always see everything at a glance – and you can configure your own website and individual newsletter.

- My watch list

- My saved searches

- My saved topics

- My newsletter

Stress relaxationStress relaxation describes how polymers relieve stress under constant strain. Because they are viscoelastic, polymers behave in a nonlinear, non-Hookean fashion.[1] This nonlinearity is described by both stress relaxation and a phenomenon known as creep, which describes how polymers strain under constant stress. Product highlightViscoelastic materials have the properties of both viscous and elastic materials and can be modeled by combining elements that represent these characteristics. One viscoelastic model, called the Maxwell model predicts behavior akin to a spring (elastic element) being in series with a dashpot (viscous element), while the Voigt model places these elements in parallel. Although the Maxwell model is good at predicting stress relaxation, it is fairly poor at predicting creep. On the other hand, the Voigt model is good at predicting creep but rather poor at predicting stress relaxation. The most accurate of the viscoelastic models is the Standard Linear Solid model, which combines the characteristics of both the Maxwell and Voigt models to display both creep and stress relaxation (See Viscoelasticity).[2] The following image shows the response of a Standard Linear Solid material to a constant stress, σ0, over time from t0 to a later time tf. For times greater than tf the load is removed. The curvature of the model represent the effects of both creep and stress relaxation. E1 and E2 refer to the spring constants of the elastic elements of the model.

Stress relaxation calculations can differ for different materials: To generalize, Obukhov uses power dependencies:[3] where σ0 is the maximum stress at the time the loading was removed (t*), and n is a material parameter.

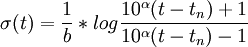

where α is a material constant and b and tn depend on processing conditions.

The following non-material parameters all affect stress relaxation in polymers :[3]

See alsoReferences |

| This article is licensed under the GNU Free Documentation License. It uses material from the Wikipedia article "Stress_relaxation". A list of authors is available in Wikipedia. |

![\sigma(t)= \frac { \sigma_0 }{ 1-[1-(t/t*)(1^{1-n})]}](images/math/7/e/1/7e150056e16906023f6ce0218bc27e05.png)

![\sigma(t)= \sum_{mn}^{} { A_{mn} [\ln(1+t)]^m (\epsilon'_0)^n}](images/math/9/7/1/9719c0c5afa10546d80730f287374d70.png)