Reaction calorimetry in microreactors

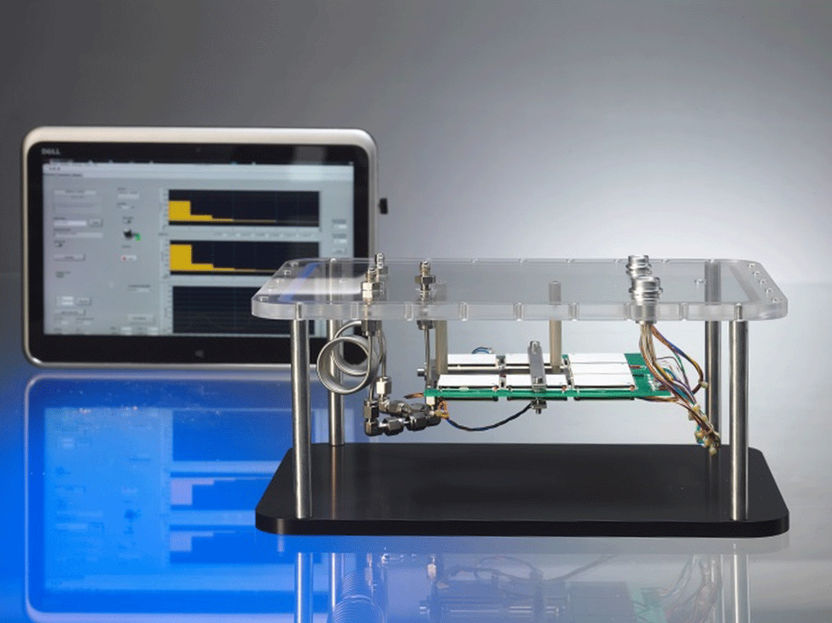

At Achema 2018 the Fraunhofer Institute for Chemical Technology will demonstrate the latest gen-eration of continuous reaction calorimeters. These permit rapid screening of thermokinetic data, making kinetic constants and safety-relevant data available in the early stages of process development.

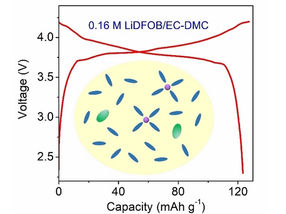

Temporally and locally-resolved reaction calorimetry in continuous reactors. The meas-urement software, which was developed on the basis of LabVIEW, enables the graphical visualization of the measured heat flows.

Fraunhofer ICT

Process design aims to develop quick, cost-effective and safe manufacturing processes in terms of synthesis, refinement and waste management. Global competition and innovation pressure predefine a limited timeframe for the development of new chemical processes. Especially in the field of specialty and fine chemistry, a significant shortening of the time-to-market is of pivotal importance for market success.

High-performance tool for process development and optimization

Fraunhofer ICT develops continuous reaction calorimeters based on microreactors, which permit the rapid screening of thermokinetic key data. The core component of the calorimeters are sensor arrays based on Seebeck elements for the localized characterization of heat flows. The sensor arrays consist of up to 40 individual sensors, which can measure the reaction heat generated in a microreactor with a high degree of temporal and spatial resolution. A variety of process parameters can be tested within a short timeframe, and their influence on the heat generation and thermal conversion can be investigated. During parameter screenings, the influence of individual process parameters (e.g. concentration, stoichiometry, use of alternative reactants, temperature, residence time, etc.) on the reaction rate can be followed directly by observing the altered heat signal – both in a qualitative and quantitative manner. In addition, even “worst-case” processing conditions can be investigated and analyzed quantitatively in terms of their energetic potential.

Flexible and high-performance

The smallest test volumes are extremely small (< 100 μl), so the consumption of substances is reduced to a minimum, which is particularly important in the case of cost-intensive chemicals. The modular design of the measuring system also permits the adaptation of the sensor arrays to a variety of reactor types and sizes. Reaction temperatures range from -80°C to +200°C and a pressure of 100 bar enables the safe investigation of new process windows.

The continuous reaction calorimeter and its applications, ranging from real-time measurement of the reaction rate through to safety investigations, are presented at the joint stand of the Fraunhofer-Gesellschaft.

Other news from the department science

Most read news

More news from our other portals

See the theme worlds for related content

Topic world Synthesis

Chemical synthesis is at the heart of modern chemistry and enables the targeted production of molecules with specific properties. By combining starting materials in defined reaction conditions, chemists can create a wide range of compounds, from simple molecules to complex active ingredients.

Topic world Synthesis

Chemical synthesis is at the heart of modern chemistry and enables the targeted production of molecules with specific properties. By combining starting materials in defined reaction conditions, chemists can create a wide range of compounds, from simple molecules to complex active ingredients.