Chemical industry will use waste gas from steel factories to make plastics

Europeans join forces on CO2

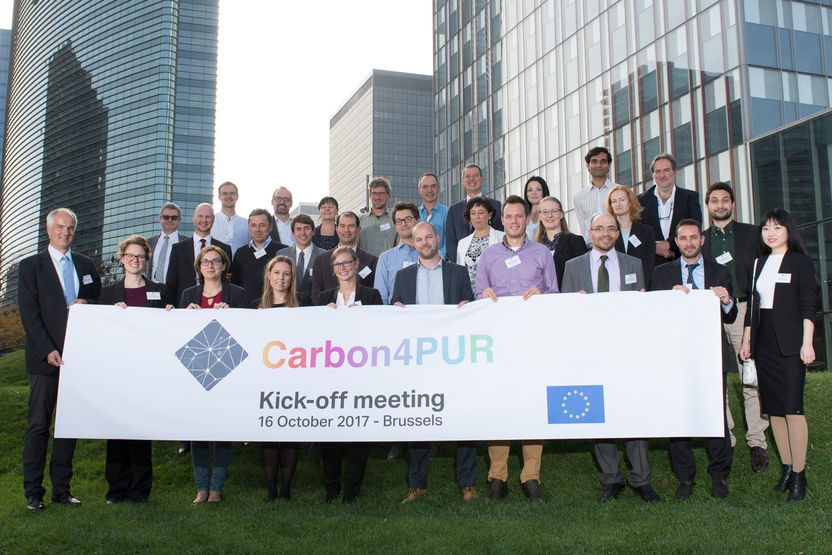

The use of carbon dioxide and other waste gases as a new source of raw materials is increasingly a topic of interest at the European level. A new consortium of 14 partners from seven countries, led by materials manufacturer Covestro, is now planning to investigate how flue gas from the steel industry can be used to produce plastics in a particularly efficient and sustainable way. This will save crude oil, the raw material used in conventional methods. The cross-sector project called Carbon4PUR receives funding from the European Union.

“Together, we are on the path to a crucial innovation: waste gas mixtures from the steel industry can provide carbon for a chemical processes and ultimately be used to produce insulation materials and coatings,” explained Dr. Markus Steilemann, the Covestro Board Member responsible for Innovation, Marketing and Sales. “This helps us to broaden our resource base and to reduce the climate footprint for the entire value chain. At the same time, we are joining our forces by partnering with industrial and academic partners throughout Europe.”

This consortium of 14 partners from seven countries, led by Covestro, is now planning to investigate how flue gas from the steel industry can be used to produce plastics in a particularly efficient and sustainable way.

Covestro AG

Cooperation across borders

The new project introduces an unprecedented cooperation extending from the waste gas source to the plastics manufacturer. The European Union is supporting Carbon4PUR under the auspices of SPIRE, the European Public-Private Partnership, dedicated to innovation in resource and energy efficiency enabled by the process industries. About eight million euros are provided for the time of three years. The industrial partners will leverage this contribution by further investments.

Specifically, the project aims to use mixtures of carbon dioxide and carbon monoxide, which are generated during steel production, to produce polyols – key components of polyurethane-based insulating materials and coatings that are otherwise obtained from crude oil.

Significantly smaller carbon footprint

The process being developed is special because it eliminates the resource intensive step of separating the waste gas into its different components. Instead, the gas mixture will be subjected to a chemocatalytic process and converted directly into building blocks and intermediates for polyurethanes. This can reduce its carbon footprint by 20 to 60 percent.

The ideal starting conditions for the industrial pilot project already exist: in the southern French town of Fos-sur-Mer, an ArcelorMittal steel factory and a Covestro production facility are close neighbours. The gas recovery project consortium includes academic and institutional partners such as RWTH Aachen University, TU Berlin, Dechema, Imperial College London, the universities of Gent and Leiden, the French Commissariat à l’énergie atomique et aux énergies alternatives, South Pole Carbon Asset Management, Grand Port Maritime de Marseille and PNO Innovatieadvies. From its base in southern France, Covestro could deliver its innovative intermediate products to additional industrial partners, such as Recticel, a Belgium-based polyurethane foam manufacturer, and Megara Resins, a Greek supplier to the coatings industry.

Last year, Covestro began using carbon dioxide to produce a precursor for soft polyurethane foam, which is designed for use in upholstered furniture and mattresses. Meanwhile, the company is researching additional areas of application for CO2-based raw materials.

Most read news

Topics

Organizations

Other news from the department science

Get the chemical industry in your inbox

From now on, don't miss a thing: Our newsletter for the chemical industry, analytics, lab technology and process engineering brings you up to date every Tuesday and Thursday. The latest industry news, product highlights and innovations - compact and easy to understand in your inbox. Researched by us so you don't have to.