To use all functions of this page, please activate cookies in your browser.

my.chemeurope.com

With an accout for my.chemeurope.com you can always see everything at a glance – and you can configure your own website and individual newsletter.

- My watch list

- My saved searches

- My saved topics

- My newsletter

Austenite

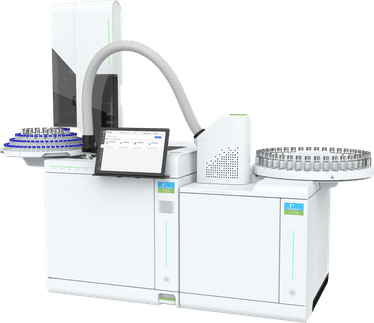

Austenite (or gamma phase iron) is a metallic non-magnetic solid solution of iron and an alloying element. In plain-carbon steel, austenite exists above the critical eutectoid temperature of 1000 K (about 727 °C); other alloys of steel have different eutectoid temperatures. It is named after Sir William Chandler Roberts-Austen (1843-1902). Product highlight

Behavior in Plain-Carbon SteelAs austenite cools, it often transforms into a mixture of ferrite and cementite as dissolved carbon falls out of solution. Depending on alloy composition and rate of cooling, pearlite may form. If the rate of cooling is very fast, the alloy may experience a slight lattice distortion known as martensitic transformation, instead of transforming into a mixture. In this industrially very important case, the carbon is not allowed to blend out in the remaining melt due to the cooling speed, but is captured inside the FCC-structure of austenite, creating tension in the crystal when the alloy cools. The result is hard martensite. The rate of cooling determines the relative proportions of these materials and therefore the mechanical properties (e.g. hardness, tensile strength) of the steel. Quenching (to induce martensitic transformation), followed by tempering will transform some of the brittle martensite into bainite. If a low-hardenability steel is quenched, a significant amount of austenite will be retained in the microstructure. StabilizationThe addition of certain alloying elements, such as manganese and nickel, can stabilize the austenitic structure, facilitating heat-treatment of low-alloy steels. In the extreme case of austenitic stainless steel, much higher alloy content makes this structure stable even at room temperature. On the other hand, such elements as silicon, molybdenum, and chromium tend to de-stabilize austenite, raising the eutectoid temperature. Austenite transformation and Curie pointIn many magnetic alloys, the Curie point, the temperature at which magnetic materials cease to behave magnetically, occurs at nearly the same temperature as the austenite transformation. This behavior is attributed to the paramagnetic nature of austenite, while both martensite and ferrite are strongly ferromagnetic. Thermo-optical emissionA blacksmith causes phase changes in the iron-carbon system in order to control the material's mechanical properties, often using the annealing, quenching, and tempering processes. In this context, the color of light emitted by the workpiece is an approximate gauge of temperature, with the transition from red to orange corresponding to the formation of austenite in medium- and high-carbon steel. Maximum carbon solubility in austenite is 2.03% C at 1420 K (1147 °C). References"Physical Metallurgy Principles". Reed-Hill, Robert. 3rd. Edition. PWS Publishing. Boston. 1991. See alsoCategories: Metallurgy | Iron |

|||||||

| This article is licensed under the GNU Free Documentation License. It uses material from the Wikipedia article "Austenite". A list of authors is available in Wikipedia. |