To use all functions of this page, please activate cookies in your browser.

my.chemeurope.com

With an accout for my.chemeurope.com you can always see everything at a glance – and you can configure your own website and individual newsletter.

- My watch list

- My saved searches

- My saved topics

- My newsletter

Electric heating

Product highlight

Design variationsAlthough they all use the same physical principle to generate heat, electric heaters differ in the way they deliver that heat to the environment. Several types are described in the sections below. Radiative heaters or "space heaters"Radiative heaters contain a heating element that reaches a high temperature. The element is usually packaged inside a glass envelope resembling a light bulb and with a reflector to direct the energy output away from the body of the heater. The element emits infrared radiation that travels through air or space until it hits an absorbing surface, where it is partially converted to heat and partially reflected. This heat directly warms people and objects in the room, rather than warming the air. This style of heater is particularly useful in areas which unheated air flows through. They are also ideal for basements and garages where spot heating is desired. More generally, they are an excellent choice for task-specific heating. They operate silently. Radiant heaters present the greatest potential danger to ignite nearby furnishings due to the focused intensity of their output and lack of overheat protection. Convection heaters

In a convection heater, the heating element heats the air next to it by conduction. Hot air is less dense than cool air, so it rises due to buoyancy, allowing more cool air to flow in to take its place. This sets up a constant current of hot air that leaves the appliance through vent holes and heats up the surrounding space. They are ideally suited for heating a closed space. They operate silently and have a lower risk of ignition hazard in the event that they make unintended contact with furnishings compared to radiant electric heaters. This is a good choice for long periods of time or if left unattended. They are very safe heaters and there is a very low chance of getting burned. In the United Kingdom, these appliances are sometimes called electric fires, because they were originally used to replace open fires. Fan heaters or "forced convection heaters"A fan heater is a variety of convection heater that includes an electric fan to speed up the airflow. This reduces the thermal resistance between the heating element and the surroundings, allowing heat to be transferred more quickly. They operate with considerable noise caused by the fan. They have a moderate risk of ignition hazard in the event that they make unintended contact with furnishings. This type of heater is a good choice for quick heating of enclosed spaces; however, they should not be left unattended. Storage heatingA storage heating system takes advantage of cheaper electricity prices, sold during low demand periods such as overnight. In the United Kingdom, this is branded as Economy 7. The storage heater stores heat in clay bricks, then releases it during the day when required. Domestic electrical underfloor heatingThese systems are called radiant heating systems, regardless of whether they include a heat exchanger (also called a radiator) or are electrically powered. When a home radiant heat system is turned on, current flows through a conductive heating material. For high-voltage radiant heat systems, line voltage (110 V or 230 V) current flows through the heating cable. For low-voltage systems, the line voltage is converted to low voltage (8 to 30 V) in the control unit (which contains a step-down transformer) and this low voltage is then applied to the heating element. The heated material then heats the flooring until it reaches the right temperature set by the floor thermostat. The flooring then heats the adjacent air, which circulates, heating other objects in the room (tables, chairs, people) by convection. As it rises, the heated air will heat the room and all its contents up to the ceiling. This form of heating gives the most consistent room temperature from floor to ceiling compared to any other heating system. Environmental and efficiency aspectsThe overall energy efficiency of direct electric heating is usually low. Most electricity is generated remotely using fossil fuels. The efficiency of generating electricity from combustion of fuels is typically only 30 to 40 percent. Thus even with a 100% efficient electric heater, the amount of fuel needed for a given amount of heat is much less than if the fuel was burned in a furnace or boiler at the building being heated. In Sweden the use of direct electric heating has been restricted since the 1980s for this reason, and there are plans to phase it out entirely - see Oil phase-out in Sweden - while Denmark has banned the installation of electric space heating in new buildings for similar reasons.[1] More efficient alternatives include hot-water (hydronic) or forced-air central heating systems. These can use high-efficiency condensing boilers, biofuels, heat pumps, cogeneration and/or district heating. Hydronic Underfloor heating offers additional advantages including the ability to be relatively easily converted in the future to use developing technologies such as solar panels, so also providing future-proofing. In the case of new buildings, low-energy building techniques can be used which can virtually eliminate the need for heating, such as those built to the Passive House standard. In order to use electricity to provide heat efficiently, a heat pump driven by electricity can boost the temperature of the heat in the ground, in the outside air, or in waste streams such as exhaust air in order to use it as a heat source. This can cut the electricity consumption down to as little as 20% and thus can also the reduce the environmental impact. Economic aspectsThe operation of electric resistance heaters to heat an area for a long period of time is generally considered to be costly. However intermittent or partial day use can be more cost efficient than whole building heating since there savings due to superior zonal control. Example: A lunch room in an office setting has limited hours of operation. During low use periods a "monitor" level of heat (50 °F/10 °C) is provided by the central heating system. Peak use times between the hours of 11:00–14:00 are heated to "comfort levels" (70 °F/21 °C). Significant savings can be realized in overall energy consumption since infrared radiation losses through thermal conductivity are not as large with a smaller temperature gradient both between this space and unheated outside air as well as between the refrigerator and the (now cooler) lunch room. Mathematical analysisAccording to Joule's Law, the heat power produced by a resistor is:

where and according to Ohm's Law I and V are related as follows:

where

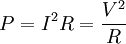

We can combine these two formulae to obtain the heat output from the heating element in terms of either current or voltage:

For heaters powered by AC mains, I and V are the root mean square (RMS) values of current and voltage. See also

References

|

|||

| This article is licensed under the GNU Free Documentation License. It uses material from the Wikipedia article "Electric_heating". A list of authors is available in Wikipedia. |