To use all functions of this page, please activate cookies in your browser.

my.chemeurope.com

With an accout for my.chemeurope.com you can always see everything at a glance – and you can configure your own website and individual newsletter.

- My watch list

- My saved searches

- My saved topics

- My newsletter

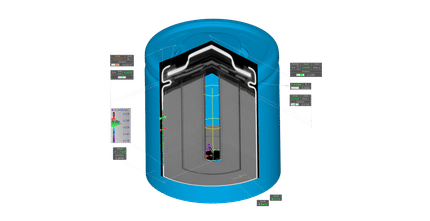

Falling film evaporatorA falling film evaporator is a device used industrially to concentrate solutions, especially solutions with heat sensitive components. The evaporator proper is a specialized heat exchanger; it consists of an outer shell which is filled with steam or other heating medium, and a number of vertical, parallel tubes through which the solution falls. The flow of the solution is controlled, so that the fluid will create a film along the inner tube walls, progressing downwards (falling) - hence the name. they said so Separation between the liquid phase (the solution) and the gaseous phase takes place in the tubes, and the change in density increases the velocity of the solution. The result is a high velocity, progressively thinner film, having an increasing turbulent flow; the combination of these effects allows very high heat transfer coefficients. A further advantage of the falling film evaporator is the very limited residence time of the liquid and the absence of superheating of the same. Not considering the vapour separator, the residence time inside the tubes is measured in seconds, making it ideal for heat-sensitive product such as milk, fruit juice, pharmaceuticals and many others. Product highlightThe pressure in the tubes may be lower than atmospheric pressure, in order to depress the solution's boiling point. |

| This article is licensed under the GNU Free Documentation License. It uses material from the Wikipedia article "Falling_film_evaporator". A list of authors is available in Wikipedia. |