To use all functions of this page, please activate cookies in your browser.

my.chemeurope.com

With an accout for my.chemeurope.com you can always see everything at a glance – and you can configure your own website and individual newsletter.

- My watch list

- My saved searches

- My saved topics

- My newsletter

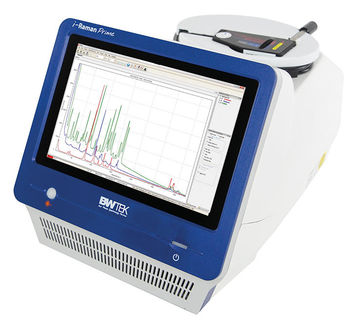

Platinum groupThe platinum group (alternatively, the platinum group metals or platinum metals) is a collective name sometimes used for six metallic elements clustered together in the periodic table. These elements are all transition metals, lying in the d-block (groups 8, 9, and 10, periods 5 and 6 — in Mendeleev's original table, this area was called "Group VIII"). The six platinum group metals are ruthenium, rhodium, palladium, osmium, iridium, and platinum. They have similar physical and chemical properties, and tend to occur together in the same mineral deposits. Product highlight

HistoryNaturally occurring platinum and platinum-rich alloys have been known for a long time. Though the metal was used by pre-Columbian peoples, the first European reference to platinum appears in 1557 in the writings of the Italian humanist Julius Caesar Scaliger (1484-1558) as a description of a mysterious metal found in Central American mines between Darién (Panama) and Mexico ("up until now impossible to melt by any of the Spanish arts"). The Spaniards named the metal platina ("little silver") when they first encountered it in Colombia. They regarded platinum as an unwanted impurity in the silver they were mining. PropertiesThe platinum metals have outstanding catalytic properties. They are highly resistant to wear and tarnish, making platinum, in particular, well suited for fine jewelry. Other distinctive properties include resistance to chemical attack, excellent high-temperature characteristics, and stable electrical properties. All these properties have been exploited for industrial applications. ApplicationsPlatinum, platinum alloys, and iridium are used as crucible materials for the growth of single crystals, especially oxides. The chemical industry uses a significant amount of either platinum or a platinum-rhodium alloy catalyst in the form of gauze to catalyze the partial oxidation of ammonia to yield nitric oxide, which is the raw material for fertilizers, explosives, and nitric acid. In recent years, a number of platinum-group metals have become important as catalysts in synthetic organic chemistry. Ruthenium dioxide is used as coatings on dimensionally stable titanium anodes used in the production of chlorine and caustic. Platinum supported catalysts are used in the refining of crude oil, reforming, and other processes used in the production of high-octane gasoline and aromatic compounds for the petrochemical industry. Since 1979, the automotive industry has emerged as the principal consumer of platinum-group metals. Palladium, platinum, and rhodium have been used as oxidation catalyst in catalytic converters to treat automobile exhaust emissions. A wide range of platinum-group metal alloy compositions are used in low-voltage and low-energy contacts, thick- and thin-film circuits, thermocouples and furnace components, and electrodes. Sources

ProductionThe production of pure platinum group metals normally starts from residues of the production of other metals with a mixture of several of those metals. One typical starting product is the anode residue of gold or nickel production. The differences in chemical reactivity and solubility of several compounds of the metals under extraction are used to separate them. A first step is to dissolve all the metals in aqua regia forming their respective nitrates. If silver is still present, this is then separated by forming insoluble silver chloride. Rhodium sulfate is separated after the salts have been melted together with sodium hydrogensulfat and leached with water. The residue is then melted together with sodium peroxide, which dissolves all the metals and leaves the iridium. The two remaining metals, ruthenium and osmium, form ruthenium and osmium tetroxides after chlorine has been added to solution. The osmium tetroxide is then dissolved in alcoholic sodium hydroxide and separated from the ruthenium tetroxides. All of these metals' final chemical compounds can ultimately be reduced to the elemental metal using hydrogen. See alsoCategories: Platinum | Chemical elements | Precious metals |

|

| This article is licensed under the GNU Free Documentation License. It uses material from the Wikipedia article "Platinum_group". A list of authors is available in Wikipedia. |