Sustainable battery cell with increased energy density

Varta Microbattery supports the project

Advertisement

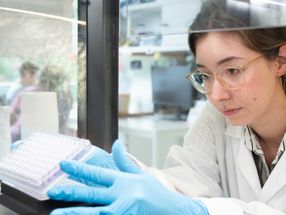

A research team at the Fraunhofer Institute for Manufacturing Engineering and Automation IPA is working on a new type of battery cell for home storage systems. It should be completely free of toxic or carcinogenic materials and have a higher energy density than conventional lithium iron phosphate battery cells.

The photovoltaic system on the roof and the home storage unit in the cellar - this is already a reality in many households today and is likely to become more and more common in the future. In the vast majority of cases, the manufacturers of both components are based somewhere in the Far East. But as far as home storage systems are concerned, this could change in just a few years. By then, a research team from the Center for Digitized Battery Cell Production (ZDB) at Fraunhofer IPA, supported by the company Varta Microbattery, wants to develop a sustainable and cost-effective high-energy round cell for home storage.

High energy density with sustainable cell materials

The scientists want to completely dispense with toxic or carcinogenic materials. So far, substances such as nickel and cobalt have been used in the electrodes. "These materials require a lot of safety technology and complex protective measures in cell production," says Johannes Wanner, Head of the Battery Systems business segment at Fraunhofer IPA. "If they are eliminated, production will inevitably become cheaper."

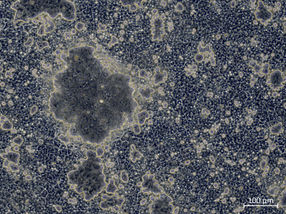

Wanner's research team is therefore focusing on a fluorine-, cobalt- and nickel-free cathode, for example a lithium manganese iron phosphate cathode (LMFP), and combining this with a high-capacity anode. In order to do justice to the concept of a sustainable battery cell, fluorine is also to be dispensed with in the electrolyte and binder, which would make the battery cell completely fluorine-free. This elimination will also improve cell safety, as hydrogen fluoride can no longer be produced.

"In battery cell production, up to 30 percent scrap is produced when changing materials to new electrode coils," says Wanner. Both a cost driver and an environmental problem. The research team wants to reduce rejects with the help of delamination: the defective coatings on the electrodes should be able to be removed and replaced at a later date. By dispensing with the fluorine-containing standard binder polyvinylidene fluoride (PVDF), a material classified as PFAS, the materials can be more easily reinstalled in new cells, thereby improving the recycling rate.

Marketable by the end of 2028

Over the past few years, the scientists at Fraunhofer IPA have set up a fully networked production line for cylindrical battery cells at the ZDB. They now want to use this to develop their sustainable high-energy round cell and scale up its production. Associated partner Varta Microbattery is supporting the project. The battery cell should be marketable by the end of 2028.

Note: This article has been translated using a computer system without human intervention. LUMITOS offers these automatic translations to present a wider range of current news. Since this article has been translated with automatic translation, it is possible that it contains errors in vocabulary, syntax or grammar. The original article in German can be found here.

Other news from the department science

Most read news

More news from our other portals

See the theme worlds for related content

Topic World Battery Technology

The topic world Battery Technology combines relevant knowledge in a unique way. Here you will find everything about suppliers and their products, webinars, white papers, catalogs and brochures.

Topic World Battery Technology

The topic world Battery Technology combines relevant knowledge in a unique way. Here you will find everything about suppliers and their products, webinars, white papers, catalogs and brochures.