Catalyst turns greenhouse gas into an energy source

Researchers convert CO₂ into methane - newly developed catalyst exceeds industry standard

Advertisement

The energy transition not only needs new sources, but also efficient storage and transportation solutions. Researchers at Kiel University (CAU) have now developed a new type of catalyst that can convert carbon dioxide (CO₂) - one of the most important greenhouse gases - into methane. The gas serves as a versatile energy source and can be fed directly into existing natural gas networks. The new catalyst is inexpensive, durable and outperforms industrial materials. The researchers have now published their results in the specialist journal "ChemSusChem", which reports on chemistry in the context of sustainability.

Professor Malte Behrens and doctoral student Anna Wolf in the synthesis laboratory at the Institute of Inorganic Chemistry at Kiel University.

© Christina Anders, Uni Kiel

Power-to-gas: storing CO₂ in methane

The underlying power-to-gas (PtG) concept stores renewable energy in chemical form. Researchers use it to produce hydrogen from electricity and react it with CO₂ to form methane. "Under real conditions, the composition of the reaction fluctuates due to the changing supply of electricity from wind and solar energy. We therefore need catalysts that work reliably even under variable conditions," says Professor Malte Behrens from the Institute of Inorganic Chemistry at Kiel University, who is leading the Kiel sub-project in the DFG Priority Program SPP 2080.

The interdisciplinary project combines chemistry, physics, materials science and engineering. Typical of the research focus "Kiel Nano, Surface and Interface Science" (KiNSIS) at Kiel University, the researchers are investigating materials from the atomic structure through to technical application and developing them further in a targeted manner.

Nanostructure ensures efficiency

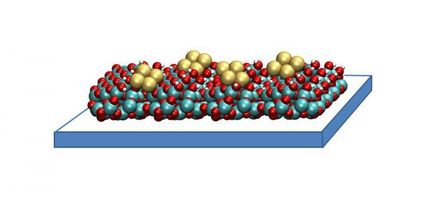

The Kiel team transferred a proven principle to the new catalyst: they specifically combined the elements nickel and magnesium at an atomic level. The joint crystallization forms a solid solution. This compound only separates shortly before the actual reaction in the reactor and tiny nickel particles are formed. The magnesium oxide stabilizes the particles and ensures that CO₂ is adsorbed particularly effectively.

"This nanoscale structure is crucial," says PhD student Anna Wolf, first author of the study. "The nickel particles remain evenly distributed and the magnesium oxide significantly supports methane production."

The result: even at comparatively low temperatures of 260 °C, the catalyst converts large quantities of CO₂ into methane. In practical terms, this means that just one kilogram of the material can produce enough methane in just under a week to heat a detached house for a year.

From laboratory to industrial application

The team attributes its success to careful optimization of all synthesis steps. "It all started with the idea of transferring a proven concept to a new material system," says Behrens. "The fact that our catalyst now outperforms industrially used materials shows the importance of systematic basic research." The researchers are transferring the laboratory results to an industrial scale and testing the catalyst under real PtG conditions together with cooperation partners at the University of Hamburg.

Note: This article has been translated using a computer system without human intervention. LUMITOS offers these automatic translations to present a wider range of current news. Since this article has been translated with automatic translation, it is possible that it contains errors in vocabulary, syntax or grammar. The original article in German can be found here.