World's Largest Scientific Society to Honor DuPont Scientists

Recognition for Two Breakthrough Discoveries in Global Security and Protection

WILMINGTON, Del., Aug. 7, 2002 - The world's largest scientific society will honor five DuPont scientists this month for two breakthrough discoveries that have strengthened security and protection measures globally.

During its 224th national meeting Aug. 18 in Boston, the American Chemical Society (ACS) and its 163,000 members will present four "Heroes of Chemistry" awards. Two of those awards will go to DuPont scientists:

-- Richard Rees -- who developed a versatile family of plastics used to make glass interlayers that minimize falling and flying glass during building explosions, storms, and transportation accidents.

-- The four-person team of W. Mark Barbour, Mark A. Jensen, George Tice, Jr. and Susan Y. Tseng which developed an innovative and accelerated system that can detect harmful pathogens in food supplies.

In its sixth year, the "Heroes of Chemistry" awards highlight the contributions of "brilliant industrial chemists and chemical engineers to their companies, to the global marketplace and to the chemical enterprise," according to ACS.

"These innovators have significantly contributed to the protection and security of our world with their technologies that detect, prevent, alleviate or remediate threats to our health and safety," said ACS president Dr. Eli M. Pearce. "The advances made serve as testimonials to the valuable role scientists play in improving our lives. It is with pride that the ACS recognizes them as `Heroes of Chemistry.'"

"For more than 200 years, DuPont has provided a breadth of world-class science and technology capabilities and, at a time when safety and protection is of the utmost importance, these recipients exemplify the scientific excellence of DuPont," said DuPont Chief Science and Technology Officer Dr. Thomas M. Connelly. "Their scientific achievements have enduring significance for our world. They are outstanding science and technology role models for those striving to unleash the next wave of innovation for our world."

Safer Glass

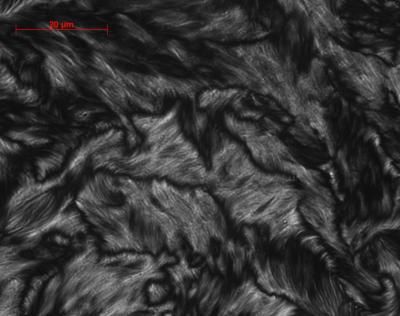

Rees invented a unique family of tough, clear plastics called DuPont(TM) Surlyn(R) ionomer resins. After Hurricane Andrew in 1992, DuPont introduced a glass interlayer, called DuPont(TM) SentryGlas(R) Plus, made with these resins for use in laminated safety glass. During a storm or explosion, the shock wave may crack the glass itself, but the fragments stick to the plastic interlayer and the pane stays within its frame. Laminated glass also helps to deflect the explosion, absorbing the blast pressure and some of the energy generated by the blast.

Windows are typically the weakest portion of a building and are the first to break in an explosion. According to the Accountability Review Board report on the 1998 embassy bombings in Kenya and East Africa, most people were killed and injured by flying glass shards and other debris. In the Oklahoma City bombing, the leading cause of injury was flying glass. By using DuPont(TM) SentryGlas(R) as a window interlayer, the windows can resist flying debris and shards of glass that could injure people.

In addition, ionomer resins have been an important part of food, medical and retail packaging. The Surlyn(R) layer of the package helps produce tough, puncture-resistant packages that protect the products inside. The resins also are used to make high-strength coatings for paper and foils. Today, most golf ball covers are made of Surlyn(R) resin. For its 35th anniversary, Golf Digest named Rees one of the top 35 contributors to the game.

Food Supply Safety

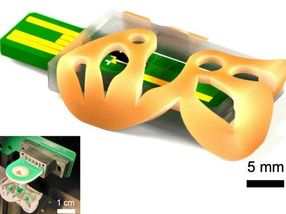

According to the U.S. Centers for Disease Control and Prevention, food- borne bacteria cause more than 76 million illnesses each year. To detect harmful food-supply bacteria, the BAX(R) system -- developed by the DuPont Qualicon science team of W. Mark Barbour, Mark A. Jensen, George Tice, Jr. and Susan Y. Tseng -- employs an innovative technique used for studying DNA called polymerase chain reaction (PCR) to detect bacteria such as E. coli, Salmonella and Listeria strains. The system is designed to identify the pathogen's DNA from other genetic information that might be found in the food ingredients or test sample. Technicians can prepare samples and run the automated system on site.

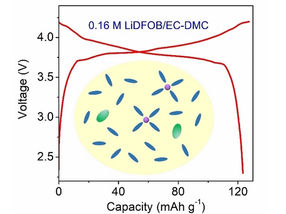

The BAX(R) system can detect bacteria in as little as 12 hours, compared to past manual practices that could take six days or more. The system reduces the reporting time for negative Listeria monocytogenes samples by one day and negative Salmonella samples by two days. It also reduces the occurrence of false positives for E. coli O157:H7.

The BAX(R) system has brought PCR into routine use in the food industry, setting a new standard for food testing. The USDA's Food Safety and Inspection Service -- which tests and regulates meat production for the United States and is considered the standard for food safety around the world -- recently adopted the BAX(R) system to test for Listeria monocytogenes. In addition, seven of the 10 largest global food companies have added the system to their food safety programs.