Plastic with a Lotus Effect

23-Aug-2004

The lotus is admired for its beauty, but that isn't all: engineers envy it for

the fascinating ability of its leaves to clean themselves, known as the lotus

effect. Never having to wash the car or windows again-that would be nice, but

it's still a long way off. Chinese researchers have now made a highly promising

step in the right direction.

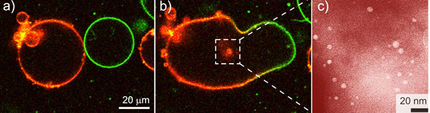

The secret of the perpetually clean lotus leaf lies in its special, extremely

water-repellent ("superhydrophobic") surface structure. It is virtually

impossible for water to wet the surface, it simply beads off, taking any

clinging particles of dirt with it. This magic is a result of the contact angle,

the angle between the surfaces of the leaf and the water droplet at the point of

contact; the more water-repellent the surface, the larger the contact angle. The

lotus leaf has an extremely rough, nanostructured surface. The water droplets

lie on it as if on a bed of nails, but there is air between the nanopeaks and

air is not at all wettable. This is thus equivalent to a contact angle of 180°.

A team led by Lei Jiang has now used polystyrene, a common plastic, to produce a

thin plastic film with superhydrophobic properties. The electrohydrodynamic

production method they use is also a very common technique. A solution of

polystyrene in an organic solvent is sprayed through a nozzle. There is a high

electrical voltage between the nozzle and the collector plate, which charges the

stream of liquid and accelerates it toward the collector. The form of the

polystyrene film that accumulates on the collector depends primarily on the

concentration of the polystyrene solution. Concentrated solutions are so viscous

that they form nanothreads as they shoot out of the nozzles. The nanothread film

has contact angles of "only" 139°. In contrast, if a dilute solution is used,

the liquid doesn't form threads, but droplets. Evaporation of the solvent causes

these droplets to solidify into porous microparticles whose surface is covered

with nanopapillae. A film of these little porous particles is extremely rough

and attains dream contact angles of 162°. Unfortunately, the particles come out

of the film. This led to the idea of a composite material that incorporates the

advantages of both textures; a finely balanced polystyrene concentration leads

to the Formation of both nanothreads and Microspheres. The porous microspheres

in the resulting film lead to a high contact angle (160.4°), while the

nanothreads fix the spheres in a stable network. This simple method also seems

to be suitable for the production of superhydrophobic films made of many other

materials.

Most read news

Other news from the department science

Get the chemical industry in your inbox

From now on, don't miss a thing: Our newsletter for the chemical industry, analytics, lab technology and process engineering brings you up to date every Tuesday and Thursday. The latest industry news, product highlights and innovations - compact and easy to understand in your inbox. Researched by us so you don't have to.