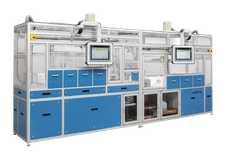

Automated sample preparation systems:

XrFuse 1 & 2 Next Generation

Automated fusion digestion for sample preparation for XRF and ICP

Fast and precise heating (up to 1,300 °C) and cooling

Flexible use for sample preparation for XRF and ICP

Upgradeable to 2 sample positions

New

New

New

New

New

New

New

New

New

New

Safe, reliable, robust. No sample contamination and flexible applications

Next generation xrFuse fusion technology has arrived.

Featuring absolute process flexibility, higher maximum fusion temperatures, advanced labware cooling and streamlined maintenance. The

xrFuse 1 is an instrument that allows for the seamless sample preparation of glass beads for XRF and ICP solutions. The system is a compact machine, ideal for lower throughput users or specialised applications. Through our proprietary quick change-out mechanism, users can alternate between XRF glass bead and ICP solutions preparations in a matter of seconds. The unit is cold-to-cold, fully CE certified, extremely safe and easy to use.

The xrFuse range has evolved from robust and reliable technology developed for high volume, high up time applications in the Iron Ore industry in Australia. This tough environment has driven the development of machines with robust components with significant lifetimes. When you buy an xrFuse, it’s built to last.

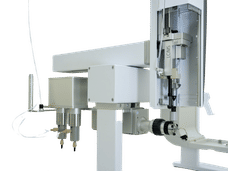

Fast, Precise Heating and Cooling

xrFuse features a highly efficient furnace chamber to reach your fusion temperature fast. Separate cooling of crucibles and moulds allows you to create the perfect glass bead and to cool crucibles to a safe temperature. Cooling inlets are filtered to ensure no external impurities interfere with your samples.

Precise temperature control and programmable

heating profiles to handle full spectrum of XRF and ICP fusions.

Streamlined Maintenance and Servicing

Simplified maintenance and servicing based on decades of experience in supporting fusion instruments worldwide.

1

XrFuse 1 & 2 New Generation

2

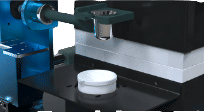

Zero Condamination

3

Process Flexibility

4

Fully Programable and Safe

5

Upgradeable to 2 Positions

Request information about XrFuse 1 & 2 Next Generation now

Automated sample preparation systems: XrFuse 1 & 2 Next Generation

Automated fusion digestion for sample preparation for XRF and ICP

Product classification XrFuse 1 & 2 Next Generation

Product categories

Applications

Manufacturers of similar products

Advertisement

Find more automated sample preparation systems and related products

Find XrFuse 1 & 2 Next Generation and related products in the theme worlds

Topic world Digestion

Sample digestion is a critical step in chemical analysis that often determines the success or failure of an investigation. It involves the targeted transformation and preparation of a sample to make the components of interest accessible for analysis. Various methods such as thermal, chemical or enzymatic digestion are used to dissolve matrix components, remove unwanted components and release target substances.

Topic world Digestion

Sample digestion is a critical step in chemical analysis that often determines the success or failure of an investigation. It involves the targeted transformation and preparation of a sample to make the components of interest accessible for analysis. Various methods such as thermal, chemical or enzymatic digestion are used to dissolve matrix components, remove unwanted components and release target substances.