Deaerators:

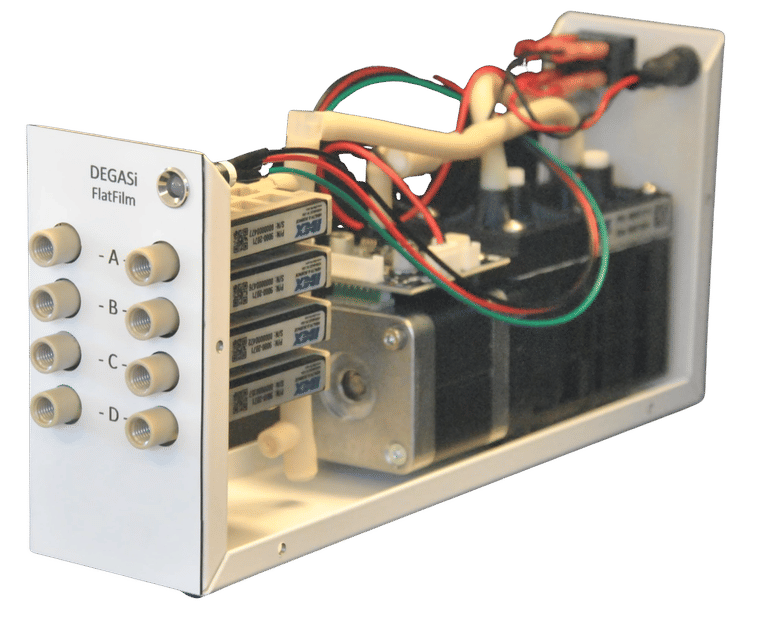

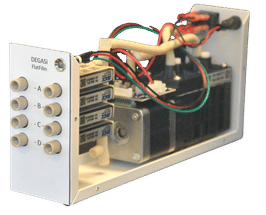

Biotech Fluidics - DEGASi® FlatFilm

The new DEGASi FlatFilm – powerful degassing for a wide range of applications

High flow rates enabled by low flow resistance, ideal for prep HPLC and HPLC/UHPLC

High chemical compatibility: stable to organic solvents, durable, process-safe

Vacuum chamber with 70% less PFAS reduces environmental impact, risks, and supports sustainability

Modern FlatFilm technology – The Fortissimo of the degasser world

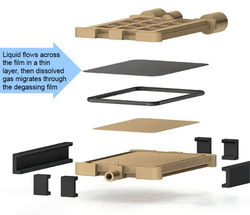

Degassing solvents is a critical factor for stable, reproducible, and high-performance analytical and process workflows. Dissolved gases such as oxygen or nitrogen can cause bubble formation in chromatographic systems, cavitation in pumps, detector baseline noise, as well as pressure fluctuations and resulting measurement deviations. This not only compromises data quality but also increases maintenance requirements and the risk of unplanned downtime. The DEGASi FlatFilm, the latest development in degassing technology, addresses these challenges with a modern, performance-optimized solution specifically designed for demanding laboratory and industrial environments.

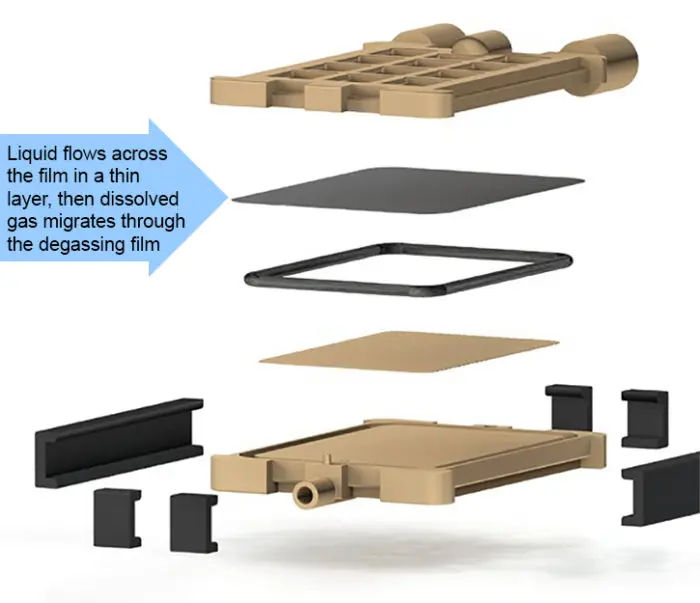

The innovative FlatFilm technology is based on a planar membrane architecture with optimized flow dynamics. It enables particularly high flow rates while maintaining low flow resistance, making it ideally suited for high-throughput applications such as modern HPLC and UHPLC systems, preparative chromatography, and continuous analytical or chemical production processes. The homogeneous membrane structure ensures efficient and uniform gas removal across the entire active surface. The result is consistent degassing performance even under changing flow rates, gradient conditions, or varying solvent compositions. Users benefit from more stable baselines, reproducible retention times, and overall more robust system performance.

Another key advantage of the DEGASi FlatFilm is its broad stability toward organic solvents. The high chemical resistance of the materials used ensures reliable operation even with aggressive or highly polar eluents. This makes the system suitable for a wide range of demanding applications, including gradient-rich methods, LC-MS applications, and specialized analyses with complex solvent mixtures. Enhanced material durability significantly extends the service life of the degasser, reduces maintenance intervals, and minimizes the risk of material-related failures. This increases process reliability and lowers long-term operating costs.

As a forward-looking development, the DEGASi FlatFilm also actively contributes to sustainability and future regulatory compliance. With up to 70% less PFAS compared to conventional solutions, it makes a measurable contribution to reducing potentially critical substances. This helps organizations meet increasing regulatory requirements and supports responsible procurement strategies. The combination of high technical performance and reduced environmental impact makes the DEGASi FlatFilm a future-ready solution for modern laboratories and industrial applications.

Overall, the DEGASi FlatFilm combines high efficiency, broad chemical compatibility, high flow rates, and improved sustainability in a compact, high-performance degasser concept.

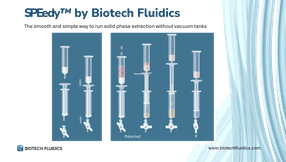

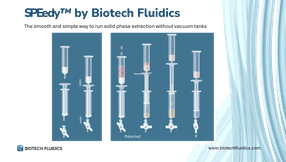

Important note: At analytica, at the Biotech Fluidics booth (Hall A1, Booth 414), visitors can discover not only the DEGASi FlatFilm but also the new SPEedy – A smart, reusable tool for fast SPE, wherever you happen to be.

1

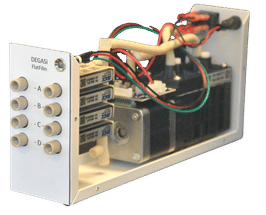

The new DEGASi-FlatFilm Degasser

2

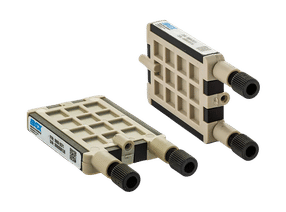

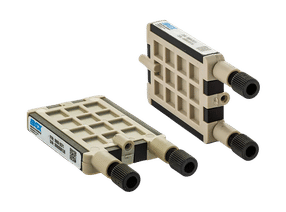

The new DEGASi-FlatFilm Degasser - Open side view

3

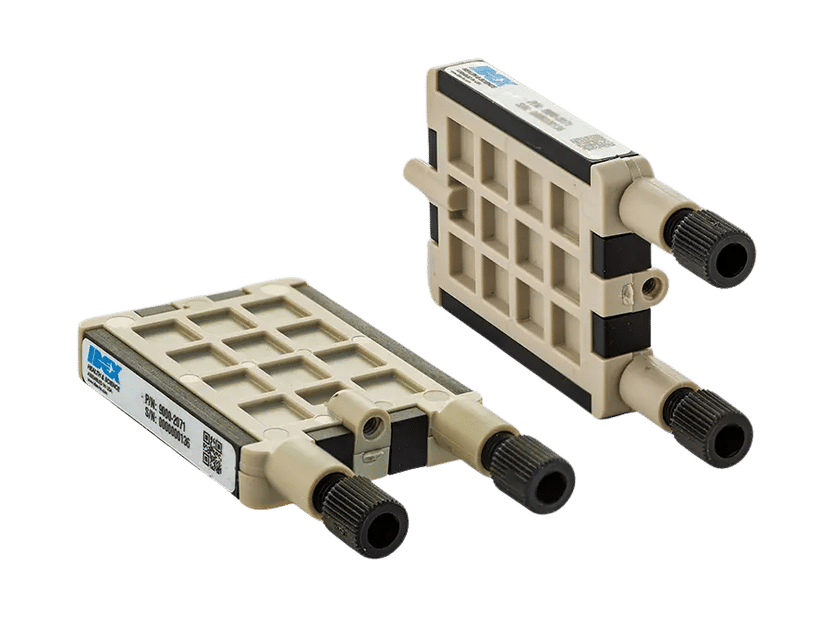

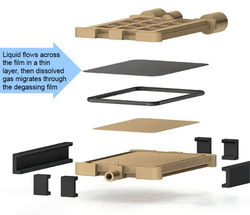

FlatFilm - Vacuum chamber

4

FlatFilm - Entgasungsprinzip

5

The new SPEedy SPE tool

Request information about Biotech Fluidics - DEGASi® FlatFilm now

Deaerators: Biotech Fluidics - DEGASi® FlatFilm

The new DEGASi FlatFilm – powerful degassing for a wide range of applications

Product classification Biotech Fluidics - DEGASi® FlatFilm

Product categories

Applications

Manufacturers of similar products

Advertisement