WACKER Builds New Pyrogenic Silica Plant in the USA

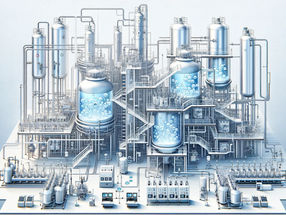

Wacker Chemie AG will build a new production plant for its HDK® brand of pyrogenic silica at its Charleston site in the US state of Tennessee. The new facility, with an annual capacity of about 13,000 metric tons, is anticipated to involve capital expenditure of some US$150 million. Construction work will start in the second quarter of next year, with completion planned for the first half of 2019. This is expected to create some 50 new jobs at the Charleston site. WACKER already produces hyperpure polysilicon for the solar and semiconductor sectors in Charleston, with some 650 employees there.

“The additional capacities strengthen our market position as a leading global producer of pyrogenic silica and help us to meet our customers’ growing demand,” said WACKER CEO Dr. Rudolf Staudigl. “The new plant is the next logical step toward expanding Charleston into a fully integrated silicon site in the world’s second-largest chemical market,” he explained, underscoring the investment’s strategic importance.

The new facility is a key addition to the Charleston site’s supply chain. The main byproduct of polysilicon manufacturing is tetrachlorosilane, which either has to be converted and fed back into the production loop or can be used to create added value by being further processed into HDK®. By integrating the polysilicon and HDK® production systems, as already operated at its Burghausen and Nünchritz sites in Germany, WACKER achieves maximum flexibility in the reprocessing of tetrachlorosilane, avoids the need to dispose of waste products, and thereby enhances the efficiency of the integrated production system as a whole.

Most read news

Other news from the department manufacturing

Get the chemical industry in your inbox

From now on, don't miss a thing: Our newsletter for the chemical industry, analytics, lab technology and process engineering brings you up to date every Tuesday and Thursday. The latest industry news, product highlights and innovations - compact and easy to understand in your inbox. Researched by us so you don't have to.