To use all functions of this page, please activate cookies in your browser.

my.chemeurope.com

With an accout for my.chemeurope.com you can always see everything at a glance – and you can configure your own website and individual newsletter.

- My watch list

- My saved searches

- My saved topics

- My newsletter

Heat pump and refrigeration cycleThermodynamic heat pump and refrigeration cycles are the models for heat pumps and refrigerators. The difference between the two is that heat pumps are intended to keep a place warm and refrigerators designed to cool it. Technically a refrigerator cycle is also a heat pump cycle. A heat pump is when heat is removed from a low-temperature space or source and rejected to a high-temperature sink with the help of external mechanical work. The inverse of the heat pump cycle is the thermodynamic power cycle. In the power cycle, heat is supplied from a high-temperature source to the heat engine, part of the heat being used to produce mechanical work and the rest being rejected to a low-temperature sink. This satisfies the second law of thermodynamics. A heat pump describes the changes that take place in the refrigerant as it alternately absorbs and rejects heat as it circulates through a refrigerator. It is also applied to HVACR work, when describing the "process" of refrigerant flow through an HVACR unit, whether it is a packaged or split system. Heat naturally flows from hot to cold. Work is applied to cool a living space or storage volume by pumping heat from a lower temperature heat source into a higher temperature heat sink. Insulation is used to reduce the work and energy required to achieve and maintain a lower temperature in the cooled space. The operating principle of the refrigeration cycle was described mathematically by Sadi Carnot in 1824 as a heat engine. The most common types of heat pump systems use the reverse-Rankine vapor-compression refrigeration cycle although absorption heat pumps are used in a minority of applications. Heat pump can be classified as:

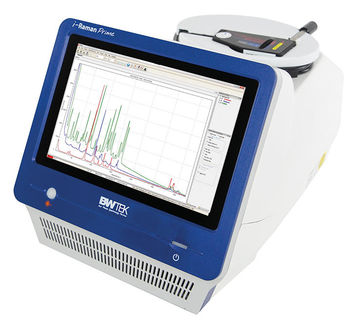

Vapor cycle refrigeration can further be classified as: Product highlight

Vapor-compression cycle

The vapor-compression cycle is used in most household refrigerators as well as in many large commercial and industrial refrigeration systems. Figure 1 provides a schematic diagram of the components of a typical vapor-compression refrigeration system. The thermodynamics of the cycle can be analyzed on a diagram[1][2] as shown in Figure 2. In this cycle, a circulating refrigerant such as Freon enters the compressor as a vapor. From point 1 to point 2, the vapor is compressed at constant entropy and exits the compressor superheated. From point 2 to point 3 and on to point 4, the superheated vapor travels through the condenser which first cools and removes the superheat and then condenses the vapor into a liquid by removing additional heat at constant pressure and temperature. Between points 4 and 5, the liquid refrigerant goes through the expansion valve (also called a throttle valve) where its pressure abruptly decreases, causing flash evaporation and auto-refrigeration of, typically, less than half of the liquid. That results in a mixture of liquid and vapor at a lower temperature and pressure as shown at point 5. The cold liquid-vapor mixture then travels through the evaporator coil or tubes and is completely vaporized by cooling the warm air (from the space being refrigerated) being blown by a fan across the evaporator coil or tubes. The resulting refrigerant vapor returns to the compressor inlet at point 1 to complete the thermodynamic cycle. The above discussion is based on the ideal vapor-compression refrigeration cycle, and does not take into account real-world effects like frictional pressure drop in the system, slight thermodynamic irreversibility during the compression of the refrigerant vapor, or non-ideal gas behavior (if any). More information about the design and performance of vapor-compression refrigeration systems is available in the classic "Perry's Chemical Engineers' Handbook".[3] Vapor absorption cycle

In the early years of the twentieth century, the vapor absorption cycle using water-ammonia systems was popular and widely used but, after the development of the vapor compression cycle, it lost much of its importance because of its low coefficient of performance (about one fifth of that of the vapor compression cycle). Nowadays, the vapor absorption cycle is used only where waste heat is available or where heat is derived from solar collectors. The absorption cycle is similar to the compression cycle, except for the method of raising the pressure of the refrigerant vapor. In the absorption system, the compressor is replaced by an absorber which dissolves the refrigerant in a suitable liquid, a liquid pump which raises the pressure and a generator which, on heat addition, drives off the refrigerant vapor from the high-pressure liquid. Some work is required by the liquid pump but, for a given quantity of refrigerant, it is much smaller than needed by the compressor in the vapor compression cycle. In an absorption refrigerator, a suitable combination of refrigerant and absorbent is used. The most common combinations are ammonia (refrigerant) and water (absorbent), and water (refrigerant) and lithium bromide (absorbent). Gas cycleWhen the working fluid is a gas that is compressed and expanded but doesn't change phase, the refrigeration cycle is called a gas cycle. Air is most often this working fluid. As there is no condensation and evaporation intended in a gas cycle, components corresponding to the condenser and evaporator in a vapor compression cycle are the hot and cold gas-to-gas heat exchangers in gas cycles. The gas cycle is less efficient than the vapor compression cycle because the gas cycle works on the reverse Brayton cycle instead of the reverse Rankine cycle. As such the working fluid does not receive and reject heat at constant temperature. In the gas cycle, the refrigeration effect is equal to the product of the specific heat of the gas and the rise in temperature of the gas in the low temperature side. Therefore, for the same cooling load, a gas refrigeration cycle will require a large mass flow rate and would be bulky. Because of their lower efficiency and larger bulk, air cycle coolers are not often applied in terrestrial refrigeration. The air cycle machine is very common, however, on gas turbine-powered 'jet' aircraft because compressed air is readily available from the engines' compressor sections. These jet aircraft's cooling and ventilation units also serve the purpose of pressurizing the aircraft. References

Categories: Thermodynamic cycles | Heat pumps |

|

| This article is licensed under the GNU Free Documentation License. It uses material from the Wikipedia article "Heat_pump_and_refrigeration_cycle". A list of authors is available in Wikipedia. |