To use all functions of this page, please activate cookies in your browser.

my.chemeurope.com

With an accout for my.chemeurope.com you can always see everything at a glance – and you can configure your own website and individual newsletter.

- My watch list

- My saved searches

- My saved topics

- My newsletter

Magnetorheological fluidA magnetorheological fluid is a type of smart fluid. It is a suspension of micrometre-sized magnetic particles in a carrier fluid, usually a type of oil. When subjected to a magnetic field, the fluid greatly increases its viscosity, to the point of becoming a viscoelastic solid. Importantly, the yield stress of the fluid when in its 'on' state can be controlled very accurately by varying the magnetic field intensity. The upshot, then, is that the fluid's ability to transmit force can be controlled with an electromagnet, which gives rise to its many potential control-based applications. Product highlight

How it worksThe magnetic particles, which are typically micrometre or nanometre scale spheres or ellipsoids, are suspended within the carrier oil are distributed randomly and in suspension under normal circumstances, as below.

When a magnetic field is applied, however, the microscopic particles (usually in the 0.1-10 µm range) align themselves along the lines of magnetic flux, see below. When the fluid is contained between two poles (typically of separation 0.5-2 mm), the resulting chains of particles restrict the movement of the fluid, perpendicular to the direction of flux, effectively increasing its viscosity. Importantly, mechanical properties of the fluid in its “on” state are anisotropic. Thus in designing a magnetorheological (or MR) device, it is crucial to ensure that the lines of flux are perpendicular to the direction of the motion to be restricted.

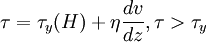

Material behaviorTo understand and predict the behaviour of the MR fluid it is necessary to be able to model the fluid mathematically, a task slightly complicated by the varying material properties (such as yield stress), but is possible. As mentioned above, smart fluids are such that they have a low viscosity in the absence of an influencing field, but become quasi-solid with the application of such a field. In the case of MR fluids (and ER), the fluid actually assumes properties comparable to a solid when in the "on" state, up until a point of yield (the shear stress above which shearing occurs). This yield stress is dependent on the magnetic field applied to the fluid, but will reach a maximum point after which increases in magnetic flux density have no further effect, as the fluid is then magnetically saturated. The behaviour of a MR fluid can thus be considered similar to a Bingham plastic, a material model which is well-investigated. However, a MR fluid does not exactly follow the characteristics of a Bingham plastic. For example, below the yield stress (in the “on state”), the fluid behaves as a viscoelastic material, with a complex modulus that is also known to be dependent on the magnetic field intensity. MR fluids are also known to be subject to shear thinning, whereby the viscosity above yield decreases with increased shear rate. Furthermore, the behaviour of MR fluids when in the "off" state is also non-Newtonian and temperature dependent, however it deviates little enough for the fluid to be ultimately considered as a Bingham plastic for a simple analysis. Thus our model of MR fluid behaviour becomes: Where τ = shear stress; τy = yield stress; H = Magnetic field intensity η = Newtonian viscosity; Particle sedimentationParticle sedimentation rate is one of the primary attributes considered in industry when implementing or designing an MR device. Surfactants are typically used to offset this effect, but at a cost of the fluid's magnetic saturation. Common MR fluid surfactantsMR fluids often contain surfactants including, but not limited to:

These surfactants serve to decrease the rate of ferroparticle settling, of which a high rate is an unfavorable characteristic of MR fluids. The ideal MR fluid would never settle, but developing this ideal fluid is as highly improbable as developing a perpetual motion machine according to our current understanding of the laws of physics. Surfactant-aided prolonged settling is typically achieved in one of two ways. In the case of the addition of soy lecithin, the surfactant particles are nanospheres and prolong the onset of settling via Brownian motion. In the case of oleic acid and other micelle surfactants, the effective diameter of each ferroparticle is increased by the attachment of micelle molecules so that they surround each ferroparticle, thereby increasing particle diameter and making fluid remixing (particle redispersion) occur far faster and with less effort. While surfactants are useful in prolonging the settling rate in MR fluids, they also prove detrimental to the fluid's magnetic properties (specifically, the magnetic saturation), which is commonly a parameter which users wish to maximize. Whether the surfactant is nanosphere-based or micelle-based, the addition of surfactants (or any other foreign particles) decreases the packing density of the ferroparticles while in its activated state, thus decreasing the fluids on-state viscosity, resulting in a "softer" activated fluid. While the on-state viscosity (the "hardness" of the activated fluid) is less of a concern for some ferrofluid applications, it is a primary fluid property for the majority of their commercial and industrial applications and therefore a compromise must be met when considering on-state viscosity vs. the settling rate of a ferrofluid. Modes of operation and applicationsA MR fluid is used in one of three main modes of operation, these being flow mode, shear mode and squeeze-flow mode. These modes involve, respectively, fluid flowing as a result of pressure gradient between two stationary plates; fluid between two plates moving relative to one another; and fluid between two plates moving in the direction perpendicular to their planes. In all cases the magnetic field is perpendicular to the planes of the plates, so as to restrict fluid in the direction parallel to the plates. Flow modeShear ModeSqueeze-Flow Mode

The applications of these various modes are numerous. Flow mode can be used in dampers and shock absorbers, by using the movement to be controlled to force the fluid through channels, across which a magnetic field is applied. Shear mode is particularly useful in clutches and brakes - in places where rotational motion must be controlled. Squeeze-flow mode, on the other hand, is most suitable for applications controlling small, millimetre-order movements but involving large forces. This particular flow mode has seen the least investigation so far. Overall, between these three modes of operation, MR fluids can be applied successfully to a wide range of applications. However, some limitations exist which it is necessary to mention here. LimitationsAlthough smart fluids are rightly seen as having many potential applications, they are limited in commercial feasibility for the following reasons:

Commercial applications do exist, as mentioned, but will continue to be few until these problems (particularly cost) are overcome. Applications

See also

References

|

|

| This article is licensed under the GNU Free Documentation License. It uses material from the Wikipedia article "Magnetorheological_fluid". A list of authors is available in Wikipedia. |

is the velocity gradient in the z-direction.

is the velocity gradient in the z-direction.