To use all functions of this page, please activate cookies in your browser.

my.chemeurope.com

With an accout for my.chemeurope.com you can always see everything at a glance – and you can configure your own website and individual newsletter.

- My watch list

- My saved searches

- My saved topics

- My newsletter

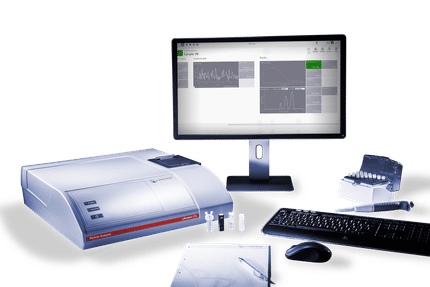

Butyl rubberButyl rubber—also known as polyisobutylene and PIB (C4H8)n is a synthetic rubber, a homopolymer of 2-methyl-1-propene. Polyisobutylene is produced by polymerization of about 98% of isobutylene with about 2% of isoprene. Structurally, polyisobutylene resembles polypropylene, having two methyl groups substituted on every other carbon atom. It has excellent impermeability, and the long polyisobutylene segments of its polymer chains give it good flex properties. Polyisobutylene is a colorless to light yellow viscoelastic material. It is generally odorless and tasteless, though it may exhibit a slight characteristic odor. The formula is: -(-CH2-C(CH3)2-)n- It can be made from the monomer isobutylene or CH2=C(CH3)2 via radical polymerization, cationic addition polymerization & anionic addition polymerization routes. A synthetic rubber, or elastomer, polyisobutylene is impermeable to air and used in many applications requiring an airtight rubber. Polyisobutylene is used in making adhesives, agricultural chemicals, fiber optic compounds, caulks and sealants, cling film, electrical fluids, lubricants (2 cycle engine oil), paper and pulp, personal care products, pigment concentrates, for rubber and polymer modification, as a gasoline/diesel fuel additive, and even in chewing gum. The first major application of butyl rubber was tire inner tubes. This remains an important segment of its market even today. Butyl rubber was first developed in 1937, by researchers William J. Sparks and Robert M. Thomas, at Standard Oil's (which became Exxon in 1972) Linden, N.J. laboratory. Texas Petrochemicals and Lubrizol Corporation are one of the largest manufacturers of PIB in North America. In 1950s and 1960s, halogenated butyl rubber (halobutyl) was developed, in its chlorinated (chlorobutyl) and brominated (bromobutyl) variant, providing significantly higher curing rates and allowing covulcanization with other rubbers like natural rubber and styrene-butadiene rubber. Halobutyl is today the most important material for inner tubes. The butyl rubber is vulcanized by elemental sulfur. Zinc oxide can be also used to vulcanize halobutyl. Product highlight

UsesFuel and lubricant additivePolyisobutylene (in the form of polyisobutylene succinimide) has interesting properties when used as an additive in lubricating oils and motor fuels. Polyisobutylene added in small amounts to the lubricating oils used in machining results in a significant reduction in the generation of oil mist and thus reduces the operator's inhalation of oil mist.[1] It is also used to clean up waterborne oil spills as part of the commercial product Elastol. When added to crude oil it increases the oil's viscoelasticity when pulled; causing the oil to resist breakup when it is vacuumed from the surface of the water. As a fuel additive, polyisobutylene has detergent properties. When added to diesel fuel, it resists fouling of fuel injectors, leading to reduced hydrocarbon and particulate emissions. [2] [3] They are blended with other detergents and additives to make a "detergent package" that is blended into gasoline and diesel fuel to resist buildup of deposits and engine knock. [4] Polyisobutylene is used in some formulations as a thickening agent. BasketballsPolyisobutylene is impermeable to air and it is normally put on the inside of basketballs to stop them deflating. References

Categories: Organic polymers | Elastomers | Fuel additives | Thickening agents |

|

| This article is licensed under the GNU Free Documentation License. It uses material from the Wikipedia article "Butyl_rubber". A list of authors is available in Wikipedia. |