Environmental award upcycling plastic bottles

VNCI rewards SABIC Innovative Plastics with Responsible Care Award 2009

Advertisement

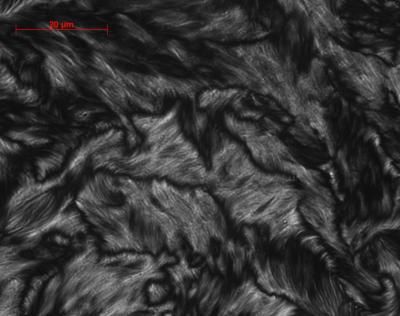

Plastic drink bottles are used by just about everyone. They are usually made from polyethylene Tereftalate, better known as PET. They often end up in the rubbish bin and then in rubbish dumps after having been used only once. SABIC Innovative Plastics has developed a system to upcycle PET waste from plastic bottles to the widely used plastic PBT (PolyButylene Tereftalate), where the quality of this ‘upcycled’ plastic is comparable with that of the original PBT. Upcycling of PET bottles has considerable environmental advantages. The Association of the Dutch Chemical Industry (VNCI) will therefore be presenting SABIC Innovative Plastics with the Responsible Care Award 2009. This award is presented each year to the chemical company that has made outstanding progress in the field of safety, health, environment, and sustainability, and is therefore an example of good practice for other companies.

SABIC Innovative Plastics uses the PET as a source for the substance TPA (tereftalic acid), which is still largely derived from fossil fuels. TPA is in turn a raw material for sustainable products based on PBT. In the first year of production, PBT produced in this sustainable way has already been used in 20 applications. The environmental benefit of this upcycling is a 55-75% reduction in CO2 emissions. It also cuts the consumption of fossil fuels for the production PBT by 55-75%. Furthermore, the SABIC Innovative Plastics' project has also reduced the volume of waste from PET bottles.

The independent jury, consisting of representatives from government organisations, environmental bodies, and chemical companies, considered this project to be a good example of Responsible Care in practice, and of the ‘cradle-to-cradle’ concept, whereby materials that have been used for one product can be used for another product without loss of quality. The jury also praised the way in which waste from outside the company was used.

Commendations

The jury gave commendations to two projects this year. AkzoNobel Industrial Chemicals (location Amersfoort) was commended for the introduction of an integrated carbon policy. A measurement technique that calculates the 'cradle-to-gate' carbon footprint is used to help reduce CO2 emissions along the entire value chain. It is applied to both the sourcing of raw materials and energy from suppliers and the production and processing in the company's own facilities, as well as the further processing of the product by its customers. The carbon policy is suitable for use throughout the entire chemical sector, and not only within AkzoNobel.

The other commendation went to BASF for the improvement in its cooling water treatment system. The best available technology has been used to replace certain components, such as the dosage installation for cooling water treatment. By replacing the dosage of chlorine dioxide with an ultrasound system, chlorine dioxide and sulphuric acid no longer need to be used to treat cooling water. Furthermore, over the last year it has managed to reduce the blow-off spray from cooling towers by 30%, and thus reduce water consumption as well.