With the Technology Center, L. B. Bohle merges all steps of continuous production for the first time

Advertisement

For many years now,continuous processes in pharmaceutical production have been the focus of the special machine builders of L.B. Bohle Maschinen + Verfahren GmbH. With the inauguration of the Technology Center, the engineers, scientists, pharmacists and IT developers for the first time closed the loop control circuit of a modular system along the entireprocess including production, sensor technology and controlling.

"Series production is set to start as soon as we have received FDA clearance. There is no need to develop, install and validate a new production line", explained Dr. Hubertus Rehbaum, Manager Scientific Operation at Bohle.

Two basic ideas are at the core of the successful development project: first of all, the best machines for the individual process steps must be optimally linked to each other, both physically and technically in terms of data. "We have leveraged our acknowledged premium quality in the areas of granulation and coating and, with the companies of Gericke and Korsch, have taken on board another two technology leaders for continuous blending/dosing and tablet press technology," said the initiator Lorenz Bohle.

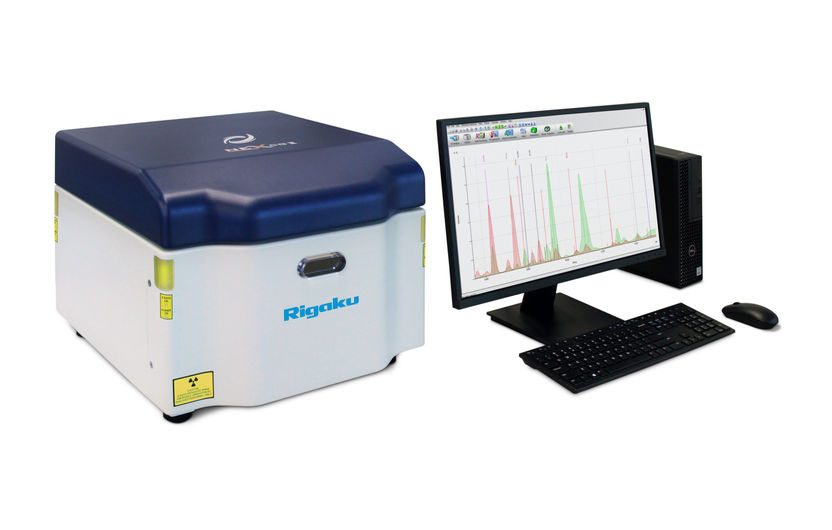

Secondly, the machines had to be equipped with state-of-the-art sensor and measurement technology and all data had to be integrated on a common platform via standardized interfaces. The software integration, in turn, forms the basis of permanent monitoring, controlling and documentation of the continuous production process. Advanced spectroscopy technologies, such as NIR and Raman, enable precise measurement and analysis during the individual production steps," explained the Manager Scientific Operation, Dr. Rehbaum. Consequently, the leading companies in this area, Kaiser Optical Systems, Sentronic and Kraemer Elektronik, have been involved in the project. Nevertheless, a major challenge arose from directly processing this generated data and making it available for use. Together with the IT partners and university scientists, models had to be developed for simulating various processes as well as for defining and automatically initiating corresponding measures and interventions. "Together, we have developed the intelligence of the system, so to speak," said Dr. Rehbaum. This “evolution process” will continue in the future.

Highly flexible plant

At the Technology Center at the Bohle headquarters in Ennigerloh, customers from the pharmaceutical industry can now experience the benefits of continuous production first hand. "The unique feature of this plant is that the tablet production can be implemented either without granulation or with dry or wet granulation, in one system“, explained Lorenz Bohle. The modular concept of continuous production offers substantial time savings since it does not require any time-consuming analyses of the product samples between the process steps. Moreover, producers benefit from greater flexibility because the plant can be quickly converted to different products.

Investments of more than two million euros

EUR 2 million has been invested in the glass-fronted building alone. "In the coming years, we will make available several million euros for the cooperation in order to push the issue of continuous production further ahead," announced the owner. The permanent measuring, monitoring and controlling of the production throughout the entire process is decisive for the customers. The investor, L. B. Bohle Maschinen + Verfahren GmbH will also manage the Technology Center. "We encourage experts to come to Ennigerloh," commented Lorenz Bohle on the breakthrough of continuous production technologies in the pharmaceutical industry.

Holistic approach as an advantage

This opportunity was also identified by the partner from the University of Düsseldorf, Prof. Peter Kleinebudde: "Given our long-standing and trustful cooperation, it was only natural to join the project as a scientific partner for developing the continuous production line". The "holistic approach" of this new form of production is especially interesting. "The objective is to link the individual process steps and to ensure consistency with constant parameters. To this day, this could not be guaranteed by science", said Prof. Peter Kleinebudde.