Waste water treatment systems:

Envochem® AOP

Removing of Highly Active Impurities – Such as Active Pharmaceuticals – from Industrial Wastewater

Modular activated oxidation process in batch mode free from residual substances

Features

- Maximum oxidation capacity thanks to state-of-the-art UV reactors with intelligent control of the UV lamps.

- Generally also suitable for turbid and coloured wastewater with a low to medium solids content

- Low oxidant consumption thanks to concentration-dependent dosing control and the option to use selected, tried and tested catalysts

- Excellent adaptability to changing contents and sudden volumes of wastewater thanks to variable setting options (such as dosages, lamp outputs and radiation times) and the ability to add further UV reactors and/or lamps

- Maximum treatment reliability thanks to a compulsory correlation study during commissioning and/or optional online monitoring of the key parameters

- Modular concept to facilitate the expansion of the plant technology.

The Envochem® AOP process

The Envochem® AOP process involves oxidising the wastewater in batches using hydrogen peroxide and UV radiation. The modular Envimodul design enables daily throughput rates of between approx. 10 m³/d and 120 m³/d. In the event of a higher daily wastewater volume, the tried and tested

Envochem® COL AOP process (continuous plant) should be used instead.

Potential applications

- Eliminating:

- Toxic content (e.g. pesticides)

- APIs (activated pharmaceuticals ingredients)

- Organic content (e.g. halogenated,

- aromatic or polycyclic hydrocarbons)

- Complexing agents (organic/inorganic)

- Inorganic components (e.g. Nitrite,

- cyanide, THS or hydrazine)

- Tensides

- Decolourising water

- Free from residual substances – no waste to dispose of

- Improving the bio-availability (BOD5/COD ratio) and/or reducing COD/TOC

High level of automation

The ASIC® controller for wastewater treatment plants is based on a freely programmable system (PLC). Both the control and plant concepts are individually adapted to suit customer requirements.

A user-friendly ASIC® touch panel makes it easy to operate, control and monitor the entire plant.

The option is also available to monitor the plant via a telephone connection (tele-service).

Envimodul sizes

Envochem® AOP type Capacity/Batch Batches / 24 h

AOP 10.000 10 m³ 1 - 2

AOP 15.000 15 m³ 1 - 2

AOP 20.000 20 m³ 1 - 2

AOP 30.000 2 x 15 m³ 1 - 2

Options

- Expansion of the oxidation plant to include the “photo-Fenton process”

- Downstream precipitation and flocculation stage including sludge dewatering

- Oxidant or neutralising agent dosing from storage tanks

- Advanced “wastewater online monitoring” in the plant outflow

- Larger sizes for installation in an engineering hall

Any hall construction work and general building services to be provided by the customer.

Subject to technical change without notice.

1

Graphical representation of wastewater oxidation process by means of hydrogen peroxide (H2O2) and UV radiation.

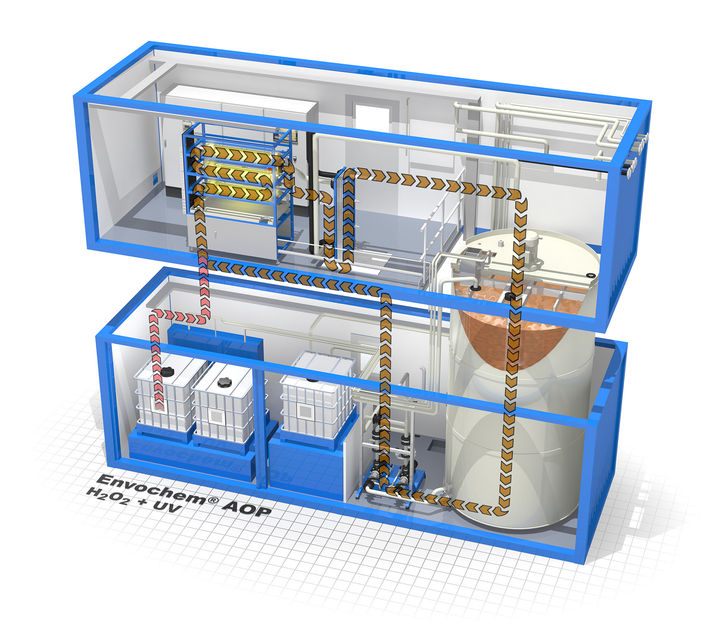

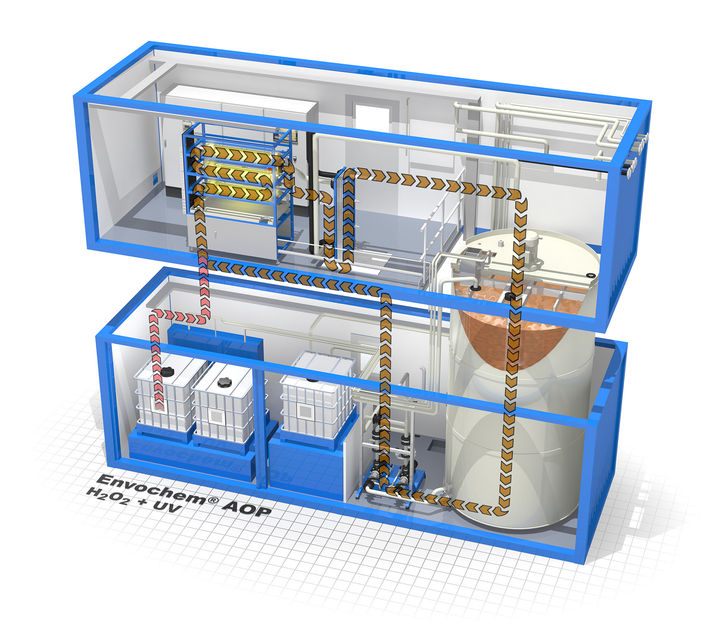

2

Internal view of an Envochem AOP modul for AOP removal

3

External view of a modular wastewater oxidation plant

4

Modular concept - simply expandable

5

Internal view of the plant module with UV radiation

Request information about Envochem® AOP now

Waste water treatment systems: Envochem® AOP

Removing of Highly Active Impurities – Such as Active Pharmaceuticals – from Industrial Wastewater