Parallel Reactor Station: Keiron S

Compact parallel reactor station with flexible volumes for research and process development.

TAD - Thermo Analytik Development AB

1–10 modular reactor cells with 24/7 data acquisition for precise, reproducible processes

Cost-effective and sustainable thanks to replaceable components within the overall system

Automated, role-based, with a wide temperature range & 2-year service

Parallel Reactor Station: Keiron S

crystallization system designed for experimental research and process analytical control.

The system features 1 to 10 independently operable reactor cells with variable working volumes of 15 ml, 85 ml, and 160 ml, customizable upon request. This modular design allows precise adjustment and reproducibility of crystallization-relevant parameters, creating controlled conditions for targeted research.

Continuous 24/7 data acquisition of all process parameters for each individual reactor cell ensures comprehensive process monitoring and enables downstream data-driven analysis. This significantly improves transparency, comparability, and scalability of experimental results.

The temperature operating range of −20 °C to 160 °C provides high methodological flexibility, allowing the study of a wide variety of material systems under varying thermodynamic conditions.

With a properly configured and scalable software architecture, Keiron S can operate either as a single instance or as multiple instances within the ame server infrastructure. This flexible and scalable system design enables adaptation to different load and application scenarios as needed. Integration of Keiron S into existing server systems is also available upon request.

Additionally, differentiated and role-based user management allows simultaneous execution of individual (private) and publicly accessible experiments within the same system environment. This ensures efficient use of resources while maintaining access control, data integrity, and experimental separation.

Process automation has been systematically optimized and functionally simplified, significantly reducing the time required to configure and implement experimental setups. This leads to increased operational efficiency, improved reproducibility of experiments, and higher throughput in research and development processes.

The purchase includes a comprehensive 2-year service contract, ensuring maximum operational reliability and predictable maintenance costs. In case of repairs, a loan device or replacement cell will be provided, allowing your research and production processes to continue without interruption.

• Modular and compact design (Plug-and-Play) – Minimal lab footprint with fast and flexible reactor cell exchange

• Budget-friendly and sustainable – Costs and waste are significantly reduced thanks to replaceable components throughout the system

• 2-year service contract and warranty – Maximum operational reliability and predictable maintenance costs, with optional extension

1

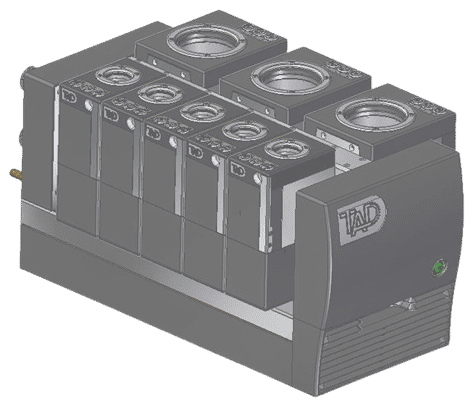

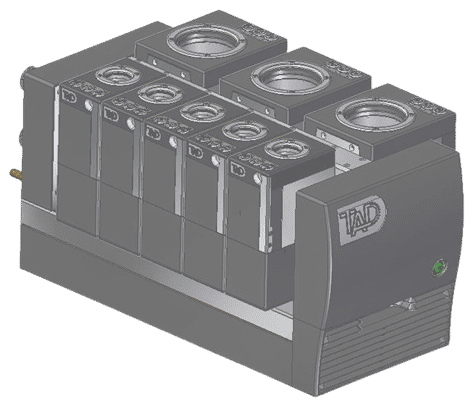

Keiron S - equipped with 3 x 160ml and 5 x 15ml cells

2

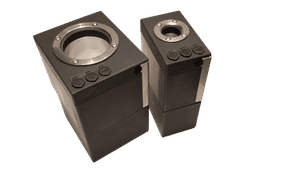

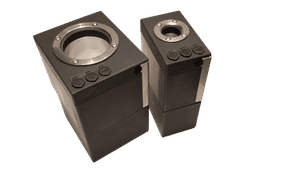

160ml and 15ml cells - (glass diameter 58mm and 25mm)

Request information about Parallel Reactor Station: Keiron S now

Multi reactor systems: Parallel Reactor Station: Keiron S

Compact parallel reactor station with flexible volumes for research and process development.

Product classification Parallel Reactor Station: Keiron S

Product categories

Applications

Manufacturers of similar products

Advertisement