Mettler-Toledo

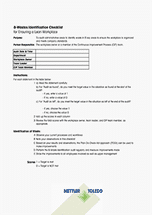

8 Wastes of Lean Laboratory - Checklist

Audit your lab efficiency

8 wastes of Lean Laboratory identification checklist is a simple way to audit the efficiency of your laboratory.

This form provides a template with which to carry out an efficiency audit of a specific laboratory and implement a continuous improvement process (CIP).

It generates an overall score (maximum 32). Any score below 20 has significant potential for improvement.

Perform the 8 wastes of lean identification audit regularly to measure and track improvements.

This free checklist consists of a series of criteria with recommended target values to meet, organized into the 8 wastes of lean categories:

1. Defects

2.Over-production

3. Waiting time

4. Non-engaged employees

5. Transport

6. Inventory

7. Motion

8. Extra processing

The 8 wastes identification checklist guides the user through the process of observing their current workflows and noting their observations, with several sub-categories for each of the 8 types of waste. A Plan-Do-Check-Act (PDCA) process can be used to make continuous improvements as a result of each audit.

Advertisement

White Paper classification

White papers on related topics

Products on related topics

See the theme worlds for related content

Topic world Weighing

Precise weighing is critical in laboratory and industrial environments. From accurate dosing of chemicals for research experiments to mass production of products, precise weight determination is often the first and most critical step. Modern balances and weighing instruments are sophisticated, offer impressive precision and are resilient to external influences such as temperature and humidity.

Topic world Weighing

Precise weighing is critical in laboratory and industrial environments. From accurate dosing of chemicals for research experiments to mass production of products, precise weight determination is often the first and most critical step. Modern balances and weighing instruments are sophisticated, offer impressive precision and are resilient to external influences such as temperature and humidity.