Iowa State, Ames Lab engineer works to develop better batteries for energy alternatives

Steve Martin, an Anson Marston Distinguished Professor in Engineering in Iowa State University's department of materials science and engineering and an associate of the U.S. Department of Energy's Ames Laboratory, is working on the electrochemical reactions that make batteries work and how new materials could be used to make better, safer batteries.

Consider the 2,140 wind turbines spinning across Iowa. They're generating 3,053 megawatts of electricity, making Iowa the second-ranked state in wind power output. Their energy production, of course, varies with the wind. And as long as production of wind energy is relatively small, the existing electricity grid can accommodate the ups and the downs. But, if wind energy climbs above 25 percent of electricity production, Martin said the grid won't be able to handle the power swings.

"We need to store that extra energy when it's generated and we're not using it, like at night," Martin said. "And so we're working on electrochemical energy storage mechanisms."

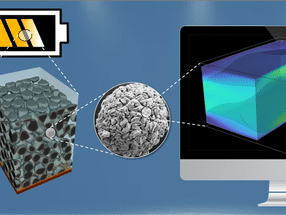

Martin has several battery projects in the works:

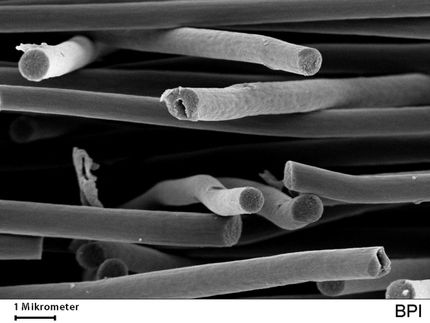

As part of a Materials World Network, Martin is working to develop better and safer lithium batteries. Network researchers are looking at replacing the liquid electrolyte that separates a battery's electron-producing anode from its electron-accepting cathode. The liquid electrolyte sometimes fails and catches fire. It also reduces battery power at cold temperatures. Martin and his collaborators are looking at a solid electrolyte made of glass. Martin's role in the project is to prepare various glasses and study their structures and conductivity. The network's project is supported by a $1 million grant from the National Science Foundation.

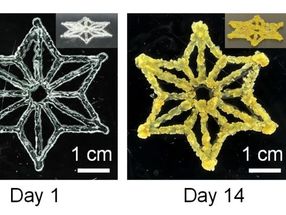

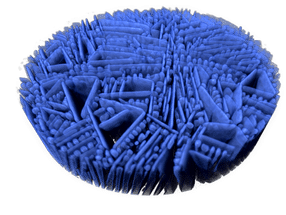

Martin is also collaborating with Iver Anderson, a senior metallurgist for the Ames Laboratory and an adjunct professor of materials science and engineering, and Emma White, a graduate student in materials science and engineering, to develop new materials for a battery's electron-producing anode. Rather than using lithium and carbon, they're studying how lithium-silicon compounds could be used. A lithium-silicon battery could hold a lot more charge, but so far the silicon anode material expands to sizes that are impractical.

"I get excited about this," Martin said. "The problem isn't the chemistry. It's can we create new structures or types of lithium-silicon phases so when the lithium comes in, the volume of the anode doesn't change?"

The project is supported by a seed grant of $50,000 from the Ames Laboratory.

Other news from the department science

Most read news

More news from our other portals

See the theme worlds for related content

Topic World Battery Technology

The topic world Battery Technology combines relevant knowledge in a unique way. Here you will find everything about suppliers and their products, webinars, white papers, catalogs and brochures.

Topic World Battery Technology

The topic world Battery Technology combines relevant knowledge in a unique way. Here you will find everything about suppliers and their products, webinars, white papers, catalogs and brochures.