Faster charging, longer lifespan

Next-generation battery breakthrough from POSTECH and KIER

Advertisement

As the demand continues to grow for batteries capable of ultra-fast charging and high energy density in various sectors—from electric vehicles to large-scale energy storage systems (ESS)—a joint research team from POSTECH (Pohang University of Science and Technology) and the Korea Institute of Energy Research (KIER) has developed a promising next-generation anode material that may address these critical needs.

Behavior of Hard Carbon–Tin Nanocomposite Anodes in Lithium-Ion and Sodium-Ion Batteries

POSTECH

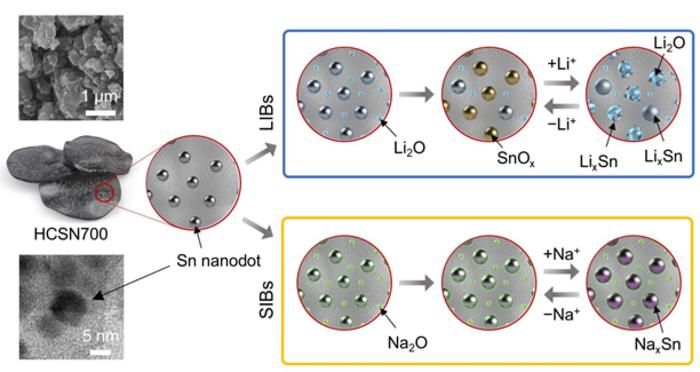

While graphite, the most common anode material in lithium-ion batteries (LIBs), offers robust structural stability, it is limited by its low theoretical capacity and sluggish charge/discharge rates. To overcome these limitations, the researchers have proposed a novel electrode design that combines hard carbon with tin (Sn).

Hard carbon is a disordered carbon material with an abundance of micropores and pathways, facilitating fast diffusion of lithium and sodium ions. This structure enables both high energy storage and mechanical robustness, making it ideal for high-rate and long-life applications.

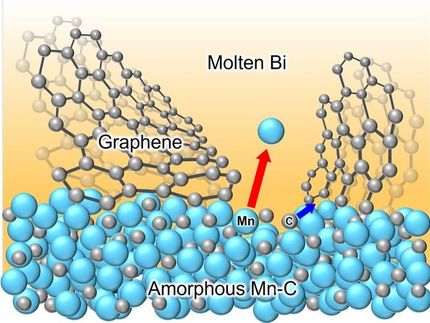

However, incorporating tin presented another challenge. The smaller the tin particles, the more effectively the problematic volume expansion during cycling is reduced, enhancing the overall stability. Unfortunately, tin's low melting point (∼230 °C) makes it difficult to synthesize such fine particles. The research team addressed this issue using a sol–gel process followed by thermal reduction, successfully embedding uniformly distributed sub-10 nm tin nanoparticles within the hard carbon matrix.

The resulting composite structure exhibits functional synergy beyond simple physical mixing. The tin nanoparticles not only act as active materials but also serve as catalysts that promote the crystallization of the surrounding hard carbon. During electrochemical cycling, the reversible formation of Sn–O bonds contributes to enhancing battery capacity via conversion reactions.

The engineered electrode has demonstrated excellent performance in lithium-ion cells, maintaining stable operation over 1,500 cycles under 20-minute fast-charging conditions, while achieving a 1.5-fold higher volumetric energy density compared to conventional graphite anodes. This achievement represents a successful integration of high power, high energy, and long cycle life in one electrode.

Remarkably, the electrode also shows outstanding performance in sodium-ion batteries (SIBs). Sodium ions generally exhibit poor reactivity with conventional anode materials like graphite or silicon. However, the hard carbon–tin nano-composite structure maintains excellent stability and fast kinetics in sodium environments, underscoring its versatility across multiple battery platforms.

Professor Soojin Park of POSTECH stated, “This research represents a new milestone in the development of next-generation high-performance batteries and holds promise for applications in electric vehicles, hybrid systems, and grid-scale ESS.” Dr. Gyujin Song of KIER added, “The realization of an anode with simultaneously high power, stability, and energy density, along with its compatibility with sodium-ion systems, marks a turning point in the rechargeable battery market.”

Original publication

Other news from the department research and development

These products might interest you

Most read news

More news from our other portals

See the theme worlds for related content

Topic World Battery Technology

The topic world Battery Technology combines relevant knowledge in a unique way. Here you will find everything about suppliers and their products, webinars, white papers, catalogs and brochures.

Topic World Battery Technology

The topic world Battery Technology combines relevant knowledge in a unique way. Here you will find everything about suppliers and their products, webinars, white papers, catalogs and brochures.