A cooperation for greener batteries

Max Planck develops sodium-sulphur batteries together with the Australian-British battery manufacturer Gelion

Advertisement

Sodium-sulphur batteries could solve a problem of the energy transition: they are intended to store electricity from wind power and photovoltaics in a cost-effective and environmentally friendly way. This is because wind and sun do not always provide energy when it is needed most. However, the service life of sodium-sulphur batteries is still limited. However, a team led by Markus Antonietti, Director at the Max Planck Institute of Colloids and Interfaces, has developed a cathode material made of sulphur and carbon, among other things, which significantly extends the service life and makes the batteries more powerful.

Symbol image

Computer-generated image

Research funding and exclusive licenses

Now the Max Planck Institute of Colloids and Interfaces has signed a cooperation agreement with the Australian-British battery manufacturer Gelion to further develop the sulphur-carbon materials for broad industrial application. "We are delighted to be working with Gelion to commercialize our breakthrough sulfur battery technology," says Markus Antonietti, Director at the Max Planck Institute of Colloids and Interfaces. "Together, we want to offer affordable, sustainable and powerful energy solutions to meet global needs."

The cooperation agreement provides for Gelion to fund the relevant research at the Max Planck Institute of Colloids and Interfaces with 600,000 euros for three years and, in return, to exclusively license patents resulting from the research. Markus Antonietti will also advise Gelion on the development of sodium-sulphur batteries as part of the cooperation. Finally, the Max Planck Institute of Colloids and Interfaces will train scientists who will then be able to pursue a career at Gelion. "This means we have embarked on a long but promising journey - from coin-sized laboratory tests to large-scale stationary batteries as an alternative to conventional lithium batteries," explains Markus Antonietti.

Sulphur-carbon nanomaterials include harmful polysulphides

Lithium-ion batteries still set the gold standard in battery technology, but lithium is a scarce resource and its use is associated with considerable ecological damage: from energy-intensive extraction and processing to the disposal of toxic residues. Sodium and sulphur, on the other hand, are abundant, inexpensive and much less harmful to the environment than some components of lithium-ion batteries. Sodium - think of ordinary table salt - can be extracted from seawater or salt deposits. Sulphur is a by-product of the oil and gas industry.

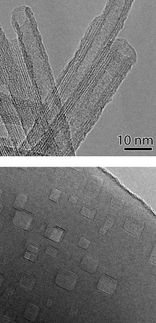

However, sodium-sulphur batteries have so far suffered from a technical problem called polysulphide shuttling - this creates soluble polysulphides that can migrate between the electrodes, damaging the battery and shortening its service life. This is precisely where the sulphur-carbon materials developed in Markus Antonietti's department could provide a remedy. This is because they are permeated by nanopores that trap the polysulphides. A test battery retained 80 percent of its original capacity after 1,500 charging and discharging cycles. In addition, the nanomaterials make it possible to use more than 99 percent of the sulphur for energy storage, thus increasing the already high energy density of a sodium-sulphur battery. "Sulphur has always enabled high energy density, but there have been issues with performance and cycle life," says John Wood, CEO of Gelion. "By combining Gelion's and Max Planck's approaches, we now have the potential to optimize all three properties in one cell."

Gelion constructs first prototypes

To date, Gelion has primarily worked on lithium-sulphur batteries, which could also become more durable and more powerful thanks to the Max Planck materials. The company will now also enter into the development of sodium-sulphur batteries and is currently constructing a prototype that is 100 times larger than the coin-sized cell from the Max Planck laboratory. "Together, Gelion and the Max Planck Institute have extraordinary capabilities," says Thomas Maschmeyer, founder and director of Gelion. "This allows us to develop a cost-effective and safe energy storage device that has very attractive performance characteristics and utilizes some of the best available elements - carbon, sodium and sulfur."

Note: This article has been translated using a computer system without human intervention. LUMITOS offers these automatic translations to present a wider range of current news. Since this article has been translated with automatic translation, it is possible that it contains errors in vocabulary, syntax or grammar. The original article in German can be found here.

Other news from the department research and development

Most read news

More news from our other portals

See the theme worlds for related content

Topic World Battery Technology

The topic world Battery Technology combines relevant knowledge in a unique way. Here you will find everything about suppliers and their products, webinars, white papers, catalogs and brochures.

Topic World Battery Technology

The topic world Battery Technology combines relevant knowledge in a unique way. Here you will find everything about suppliers and their products, webinars, white papers, catalogs and brochures.