Breakthrough in the machining of aspherical lenses

Advertisement

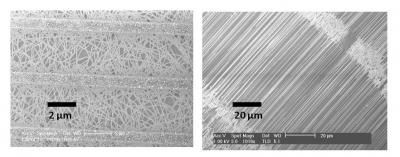

Using a new production technology Schott Guinchard of Switzerland has been successful in speeding up the machining and polishing of high-precision aspherical lenses and further improving their quality. The precision of the new process is 0.1 - 0.6 µm PV with a surface roughness of <10 angstrom RMS for lenses between 10 and 200 mm in diameter.

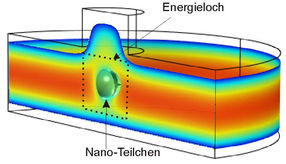

Magneto-Rheological Finishing (MRF) solves one of the classical problems in the high-precision machining of optics: tool wear with local polishing. This means that the result of the work can be calculated by means of computer simulation before the actual polishing process is carried out.

Instead of traditional grinding tools a liquid transformed into a solid in a magnetic field is used to machine and polish such materials as glass, fused silica, calcium fluoride or sapphire.

The company's flat substrate polishing capacity has also been expanded to enable it to process components with a diameter of up to 470 mm instead of 280 mm as previously. Added capacity in the company's cleanrooms provides facilities for the packaging of optical components directly following ultrasound cleaning and inspection.

Most read news

Other news from the department science

Get the chemical industry in your inbox

By submitting this form you agree that LUMITOS AG will send you the newsletter(s) selected above by email. Your data will not be passed on to third parties. Your data will be stored and processed in accordance with our data protection regulations. LUMITOS may contact you by email for the purpose of advertising or market and opinion surveys. You can revoke your consent at any time without giving reasons to LUMITOS AG, Ernst-Augustin-Str. 2, 12489 Berlin, Germany or by e-mail at revoke@lumitos.com with effect for the future. In addition, each email contains a link to unsubscribe from the corresponding newsletter.

Most read news

More news from our other portals

Last viewed contents

Atropisomer

Zedoary

Propan-1-ol_(data_page)

Diamagnetism

List_of_UN_Numbers_2501_to_2600